1 Inch Mandrel Bent Tubing

Hey there! So, you’re probably wondering, “What in the heck is 1-inch mandrel bent tubing and why should I care?” Well, grab your coffee, or your tea, or that ridiculously fancy latte you’re sipping, because we’re about to dive into something pretty cool. And no, it’s not that kind of bending. We’re talking metal here, people!

Imagine you’ve got a project brewing. Maybe it’s something awesome for your car, or a slick new furniture design, or even a crazy contraption you dreamt up after watching too many sci-fi movies. You need some sturdy pipes, right? But you don’t want them to look all crimped and sad. That’s where this little hero swoops in. Mandrel bent tubing, my friends. It’s a game changer.

So, what’s the big deal with the “mandrel” part? Think of it like this: when you bend regular old pipe, especially tight curves, the inside of the bend tends to get all squished. It’s like trying to fold a wet napkin – you end up with a mess. The metal collapses, losing its shape and, let’s be honest, its dignity.

But a mandrel? It’s this clever little gadget, like a super-strong rod, that gets shoved inside the tube before it’s bent. It’s like giving the pipe a supportive hug from the inside, preventing it from collapsing. Pretty neat, huh? So, when they bend it, it stays perfectly round. No kinks, no weird bulges, just a nice, smooth, consistent curve. It’s almost… elegant. For a piece of metal, anyway.

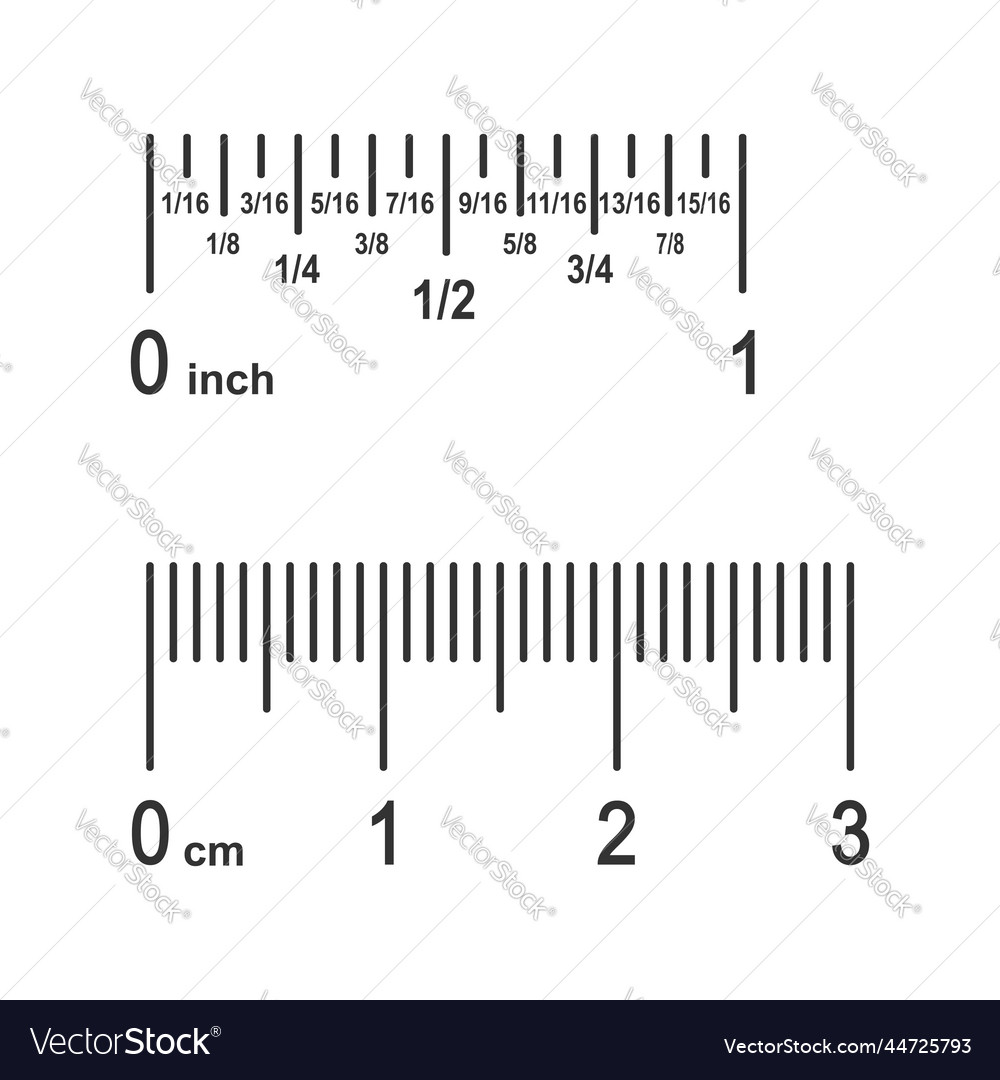

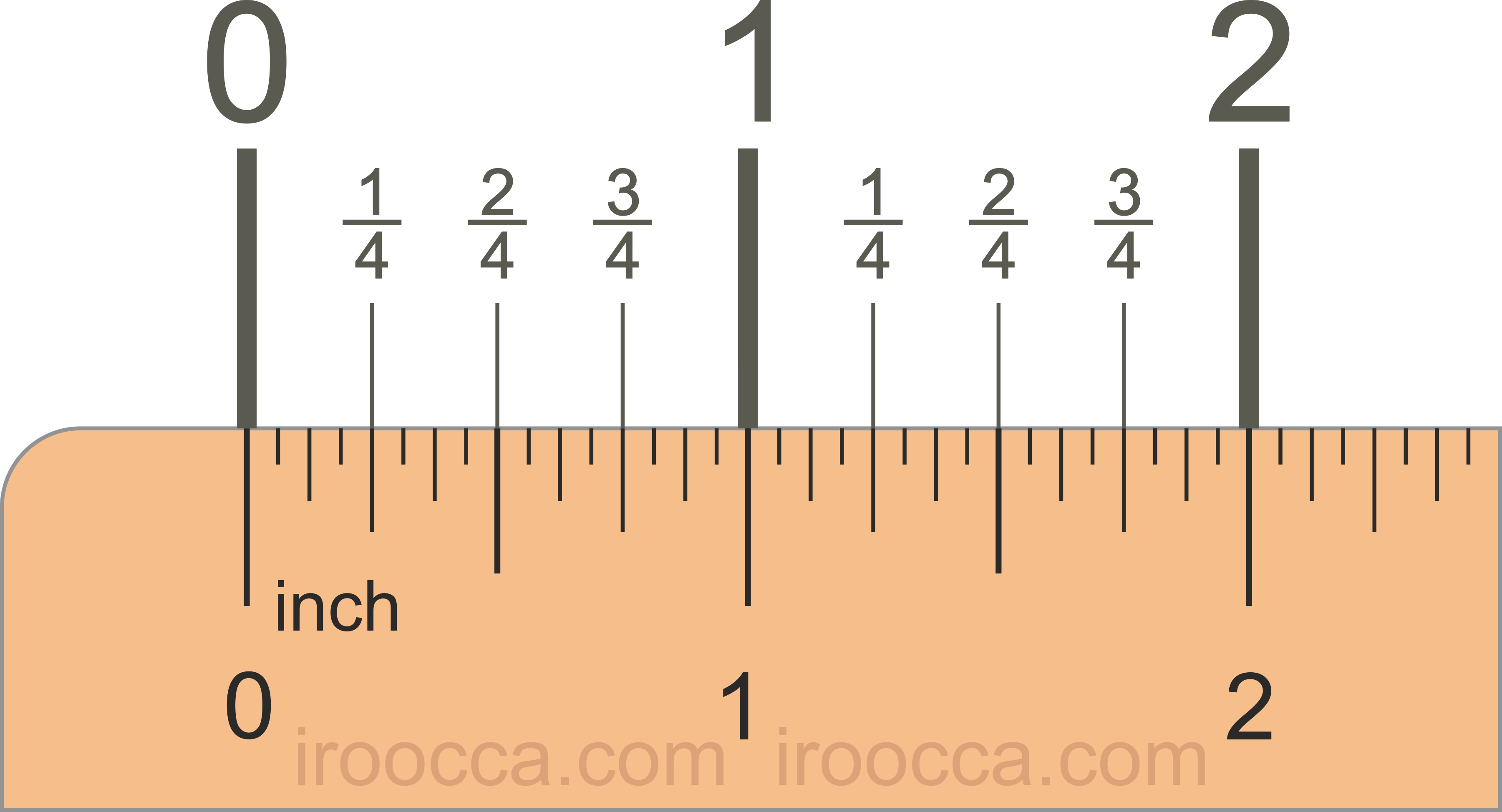

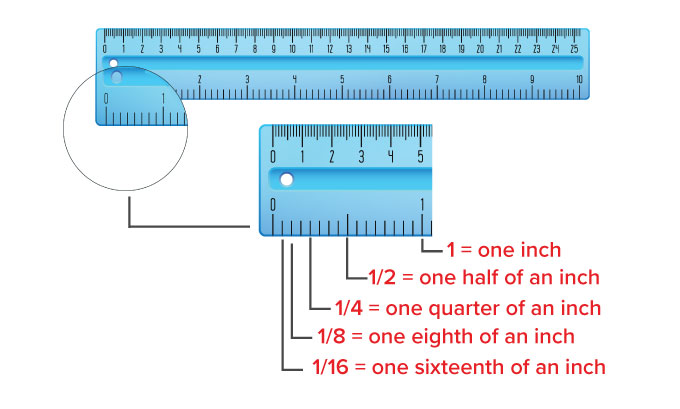

And the “1 inch” part? That’s just the diameter. Simple as that. Easy to measure, easy to work with. It’s a pretty common size for a lot of DIY projects and professional applications alike. Not too tiny, not too huge. Just right. Like Goldilocks’s favorite pipe, I guess.

Why is this so important, you ask?

Well, let’s talk about flow. If you’re using this tubing for, say, an exhaust system on your hot rod, you want the exhaust gases to flow as smoothly as possible, right? Kinks and squishes are like speed bumps for those gases. They create turbulence, they reduce efficiency, and they can even make your engine work harder than it needs to. Who wants that?

With mandrel bent tubing, the inside is nice and open. The gases (or liquids, or whatever you’re pushing through it) can just glide through, like a well-oiled machine. It’s all about efficiency and performance. Makes your engine purr instead of wheeze, you know?

And it’s not just about performance. It’s about how it looks. Ever seen a project that’s functional but looks… a bit rough around the edges? Yeah, me too. Mandrel bends give you those clean, sweeping curves that make your project look professional. Like it rolled right off a factory line, but way cooler because you made it.

So, what kind of shenanigans can you get up to with 1-inch mandrel bent tubing?

Oh, the possibilities are practically endless! Let’s brainstorm a little, shall we? Imagine you’re building a custom exhaust for your classic car. You need those nice, smooth bends to hug the chassis and clear all those important bits. Mandrel bends are your best friend here. They prevent that dreaded backpressure that can choke your engine.

Or maybe you’re into custom motorcycle fabrication. Those sweeping pipes on a chopper? They often start as plain old tubes that get expertly bent into shape. And for that sleek, minimalist look you see on some modern bikes? Yep, you guessed it, mandrel bends are key. They give you that seamless, flowing aesthetic.

How about furniture? Think about those cool industrial-style tables or shelves. You can use 1-inch tubing to create the frame. Imagine a sleek, minimalist coffee table with legs made from these perfectly bent pipes. It’s got that modern, edgy vibe. Or maybe some funky shelving units for your garage or workshop. The possibilities are seriously impressive.

And let’s not forget the world of… well, let’s call it “creative engineering.” Think about custom radiators for unique builds, or intercooler piping for turbocharged engines. The need for smooth, unrestricted flow is paramount. You don’t want your engine gasping for air like it’s running a marathon uphill!

What about something a little less… engine-y? Perhaps you’re building a custom roll cage for a track car. Safety is, like, super important, right? You need strong, perfectly shaped tubes to protect the driver. Mandrel bends ensure that the structural integrity of the cage is maintained, even on those tight corners.

Or what if you’re just a fan of DIY home decor? You could create a super-modern floor lamp with a curved base, or a minimalist coat rack with elegantly bent arms. It’s a fantastic way to add a touch of bespoke style to your living space. Forget those boring, mass-produced items. You can create something truly unique!

The nitty-gritty: Why choose 1-inch specifically?

Okay, so why 1 inch? It’s a really versatile size. It’s strong enough for many structural applications, but not so bulky that it’s difficult to work with. You can weld it, cut it, and shape it without needing a full-blown industrial workshop. It’s a sweet spot for a lot of hobbyists and even some smaller-scale professional jobs.

Think about it. Too small, and it might not be strong enough for the loads you’re putting on it. Too big, and it can be heavy, expensive, and a pain to maneuver. One inch feels… just right. It’s like the happy medium of the tubing world. Plus, it looks pretty darn good when it’s all polished up.

And the fact that it’s mandrel bent means you don’t have to worry about compromising the strength or integrity of that 1-inch diameter. You’re getting the full 1 inch of space all the way through those curves. No sneaky bottlenecks here!

What are the benefits summarized? Let’s be super clear.

So, to recap, why should you be excited about 1-inch mandrel bent tubing? Let’s break it down like a cheap souvenir on vacation:

- Smooth Bends, No Collapses: This is the big one. No kinks, no squishes. Your project will look cleaner and perform better.

- Enhanced Flow: Whether it’s air, gas, or liquid, smooth passages mean better movement. Less resistance, more efficiency.

- Superior Strength: Because the tube isn’t compromised during bending, it retains its structural integrity.

- Aesthetic Appeal: Clean, sweeping curves look professional and stylish. It elevates the look of any project.

- Versatility: 1-inch is a great all-around size for countless applications.

- Durability: Good quality tubing, bent properly, will last a long time.

Basically, it’s the difference between something that works and something that works well and looks awesome doing it. It’s the difference between a functional prototype and a finished masterpiece.

Where can you get your hands on this magical metal?

You’d be surprised! Many metal fabrication shops will carry it. Online retailers are also a fantastic resource. You can often buy it pre-bent in specific radius sizes, or you can buy it in straight lengths and have it bent yourself if you have the right equipment. Some specialized automotive parts suppliers will have it for exhaust or intake systems.

When you’re shopping, make sure you’re looking at the material. Common materials include stainless steel (great for corrosion resistance and a shiny finish), mild steel (easier to weld and cheaper), and aluminum (lightweight and corrosion-resistant, but a bit trickier to weld). The choice depends on your project’s needs and your budget. Stainless steel is often the go-to for that premium look and feel, but mild steel is perfectly fine for many applications where it’s going to be painted or protected.

And don’t be afraid to ask questions! The folks who sell this stuff are usually pretty knowledgeable. Tell them what you’re planning to do, and they can help guide you toward the right type of tubing and bend radius. It’s like having a friendly metal guru at your disposal!

A word of caution (but not too much of one!)

Now, bending tubing yourself without a mandrel can be a real headache. You can do it, sure, but you’ll likely end up with those dreaded kinks. There are other methods, like using a pipe bender with bending dies that are designed for specific tube sizes, but a mandrel bender is the gold standard for truly perfect bends. If you’re serious about getting those smooth, consistent curves, a mandrel bending service or pre-bent sections are your best bet.

And remember, safety first! When you’re working with metal, even something as relatively simple as 1-inch tubing, always wear your safety glasses, gloves, and appropriate protective gear. Sparks can fly, sharp edges exist, and nobody wants a trip to the emergency room. We’re building cool stuff, not joining the circus of occupational hazards.

So, there you have it. 1-inch mandrel bent tubing. It’s not just a fancy name for a piece of pipe. It’s a ticket to better performance, cleaner aesthetics, and the satisfaction of building something truly awesome. It’s the unsung hero of countless projects, quietly enabling smooth flow and beautiful curves.

Next time you’re sketching out your next big idea, or scrolling through inspiration online, keep this little marvel in mind. It might just be the key to unlocking the full potential of your next creation. Now go forth and bend some metal (the right way)! And maybe send me a picture of what you build. I’m genuinely curious!