Aluminum Wire For 200 Amp Service

So, picture this: I’m helping my buddy Dave move into his new fixer-upper. The kind of place where you step inside, and the air just screams "project." Dust bunnies the size of small rodents are doing interpretive dance in the corners, and the wallpaper is… let’s just say it’s seen better decades. Dave, ever the optimist, is already talking about his dream kitchen with an induction range that could probably cook a Thanksgiving turkey in 30 minutes. I, on the other hand, am cautiously eyeing the fuse box, which looks like it’s made from a relic of the Roman Empire. Then Dave points to a bundle of wires snaking out from the main panel. “All good, right?” he asks, beaming. I just nod, a little too slowly, and mentally start calculating how many trips to the hardware store we’ll need for things that aren’t questionable.

That little anecdote, while slightly terrifying, really brings us to the heart of a pretty significant electrical topic: aluminum wire for 200 amp service. It’s the kind of thing that can make even the bravest DIYer sweat a little. You see, when you’re talking about powering a modern home, especially one with all those fancy appliances Dave dreams of, you need serious juice. We’re talking about 200 amps, folks. That’s a lot of electricity flowing through those wires, and if you get it wrong, well, let’s just say your dust bunnies might start a small bonfire.

Now, before we dive headfirst into the aluminum abyss, let’s have a quick chat about what “200 amp service” even means. Think of it as the main highway for electricity entering your house. A 200 amp service means your electrical system can handle a maximum of 200 amps of current at any given time. This is the standard for most new homes and significant renovations today, and it’s pretty much the bare minimum if you want to run everything from your microwave and electric car charger to your air conditioning without tripping breakers like a game of whack-a-mole.

So, where does aluminum fit into this picture? Well, historically, copper was king. It’s an excellent conductor, durable, and has been the go-to for electrical wiring for ages. But, as you’ve probably noticed, copper prices can be a bit… volatile. They go up, they go down, they do the cha-cha with the global economy. In the past, to make things more economical, manufacturers started exploring aluminum as an alternative for certain applications. And that’s where our friend, the aluminum wire for 200 amp service, comes in.

Now, here’s where things get a tiny bit controversial, and you might want to lean in a little closer. Aluminum wiring for residential use really gained some traction in the 1960s and 1970s. The idea was simple: it was cheaper, and it was lighter, making it easier to handle on large jobs. Sounds like a win-win, right? For a while, it seemed like it. Homes wired with aluminum were built, and life went on. But then, some… issues started cropping up.

The biggest concern with older aluminum wiring was its tendency to expand and contract with temperature changes more than copper. Imagine a tiny, invisible dance happening at every connection point. This constant subtle movement could loosen connections over time. Loose connections, my friends, are the electrical equivalent of a leaky faucet – annoying at first, but potentially catastrophic later. When a connection isn't snug, it creates resistance. Resistance means heat. And heat, as we all know, is the arch-nemesis of electrical safety. This is what led to a significant number of electrical fires.

So, it’s no wonder that the mention of aluminum wire can send shivers down the spines of seasoned electricians. They’ve seen the aftermath. They’ve dealt with the repairs. It’s like a bad breakup; once bitten, twice shy, you know? And honestly, who can blame them? Electrical fires are no joke. They can destroy homes and, tragically, endanger lives.

However, here’s where the story gets a bit more nuanced, and where you might want to take a deep breath. Technology, as it tends to do, marches on. The aluminum wiring that caused problems in the past isn't necessarily the same stuff being discussed today. Modern aluminum alloys and, crucially, the proper installation techniques and termination devices have been developed to address those earlier concerns.

When we talk about aluminum wire for 200 amp service today, we’re usually referring to specific alloys, like AA-8000 series aluminum. These alloys are designed to be more resistant to oxidation and creep (that’s the technical term for the tendency to deform under sustained load, like expanding and contracting). They’ve been engineered to perform better in electrical applications.

But here’s the real kicker, and this is super important: it's not just the wire itself, but how it's connected. For older aluminum wiring, using standard copper-rated devices (like outlets and switches) was a recipe for disaster. They weren’t compatible. Think of trying to connect two puzzle pieces from different boxes – it just doesn’t work. For modern aluminum wiring, you absolutely must use connectors and devices specifically rated for aluminum, often marked with a “CO/ALR” designation. These devices are designed to accommodate the properties of aluminum and provide a secure, reliable connection.

This is where the irony really hits home. People see the word "aluminum" and immediately think "fire hazard." And historically, they weren't entirely wrong! But today, when installed correctly with the right components, aluminum can be a perfectly safe and viable option for 200 amp service. It’s like judging a modern electric car by the standards of a Model T Ford – completely unfair and misses the advancements.

So, what does this mean for you, the homeowner, the renovator, the person trying to figure out the electrical spaghetti in their basement? First and foremost, always consult with a qualified electrician. I cannot stress this enough. Electrical work is not the place for guesswork or "watching a few YouTube videos." If you’re dealing with existing wiring, an electrician can assess its condition, identify any potential risks, and recommend the best course of action. If you’re planning a new installation or a major upgrade, they will know the current codes and best practices.

When it comes to 200 amp service, the main feeders from the utility to your main panel are often aluminum. This is a common and accepted practice in many areas. The conductors carrying the power from the utility meter to your main breaker are substantial, and aluminum is a cost-effective choice for these heavy-duty applications. The key here is that these are typically installed by utility companies or their contractors, who have established protocols and use specialized equipment.

The real confusion and concern often arise when people start talking about aluminum wiring within the house, especially for branch circuits that feed individual outlets and lights. This is where the historical problems were most prevalent. While modern aluminum can be used for these circuits, it requires extreme diligence in ensuring proper wire type, connectors, and devices are used. Many electricians, out of an abundance of caution and a desire to avoid potential callbacks, will still strongly prefer copper for branch circuits.

Think about it from their perspective. If they can use copper, which has a long track record of reliability and is more forgiving of minor installation errors (though still requires proper technique!), why risk the potential headaches associated with aluminum, even if it’s the newer, improved kind? The peace of mind for both the electrician and the homeowner is often worth the extra cost of copper for those smaller circuits.

However, there are situations where aluminum might still be considered for branch circuits, perhaps in very large commercial or industrial settings where the cost savings become more significant, or where specific code requirements might favor it. But for your average residential 200 amp service, the debate often boils down to risk tolerance and cost. You're looking at 200 amps, which means you're dealing with larger gauge wires. For these larger wires, aluminum becomes a more attractive option from a cost perspective.

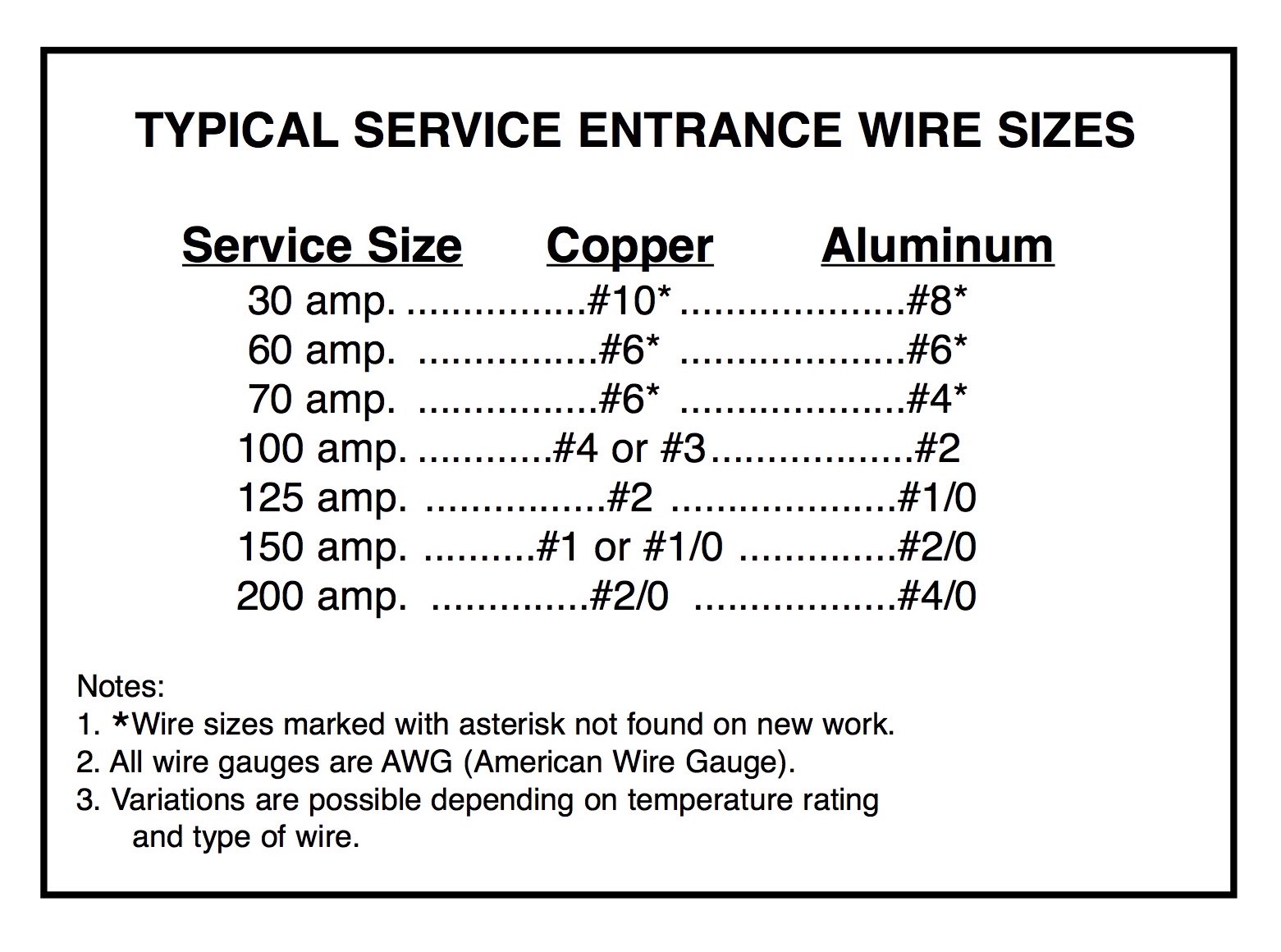

Let’s get a bit technical for a second, shall we? The size of the wire needed for 200 amp service is significant. You’re typically looking at something in the range of 2/0 AWG (American Wire Gauge) or even larger, depending on the type of conductor (solid or stranded) and the length of the run. For these sizes, the weight and cost difference between aluminum and copper can be substantial. A few hundred feet of 2/0 AWG copper cable can be a lot heavier and considerably more expensive than its aluminum counterpart.

This is where the economic argument for aluminum for 200 amp service feeders becomes stronger. If your main service entrance conductors are aluminum, it’s because the cost savings are significant, and the installation is typically handled by professionals who understand the material's properties and the required termination methods. The utility company certainly wouldn’t use something they deemed unsafe for their infrastructure, right? So, if you see aluminum coming from the pole to your meter, you can take a small breath of relief knowing that it’s a standard practice.

The real DIY minefield, if you will, comes into play if you’re looking to replace your entire service panel or run new feeders yourself. This is where you need to tread with extreme caution. If the existing panel was wired with old aluminum, an electrician will be looking for signs of corrosion, loose connections, or overheating at the breaker terminals. They might recommend upgrading the panel and replacing any problematic aluminum wiring with copper or, if appropriate, with the newer, properly terminated aluminum.

The key takeaway here, and I want to drill this in like a tiny electrical nail, is proper installation and compatible components. You cannot, I repeat, cannot treat aluminum wire the same way you treat copper. It requires specialized techniques, specialized tools (like antioxidant paste for connections), and specialized devices (the CO/ALR rated stuff). Without these, you’re inviting trouble. It’s like trying to fix a modern smartphone with a butter knife – it’s just the wrong tool for the job.

Some electricians will outright refuse to work with aluminum for anything other than the main service feeders, no matter how modern the alloy. They’ve had too many bad experiences. Others are comfortable using it for larger gauge conductors, like those found in 200 amp service, provided all the correct procedures are followed. It’s a matter of comfort level, experience, and adherence to the latest electrical codes.

So, if you’re Dave, dreaming of your induction cooktop, and your home has 200 amp service, what should you be looking for? If your service entrance conductors are aluminum, that’s likely normal. If you’re considering any upgrades or renovations that involve your wiring, or if you’re noticing any flickering lights, warm outlets, or strange smells (seriously, if you smell burning plastic, evacuate and call the fire department immediately!), it’s time to call in the pros. They’ll be able to tell you if your aluminum is the old, problematic stuff, or the newer, more robust alloy, and if it’s been installed correctly.

Ultimately, the choice between copper and aluminum for 200 amp service, especially for the main feeders, often comes down to economics and engineering. Aluminum offers a significant cost advantage for the large conductors required. When installed according to modern standards with the correct termination devices, it is a safe and reliable conductor. However, the historical reputation of aluminum wiring, and the potential for catastrophic failure if mishandled, means that caution and expertise are paramount. Don’t be afraid of aluminum wire, but be very respectful of it. And always, always, always let a qualified professional be your guide. They’re the ones who can tell the difference between a safe, modern aluminum installation and a ticking electrical time bomb. Now, if you’ll excuse me, I think Dave and I need to have a serious chat about that fuse box before we even think about that induction range.