Best Blade To Cut Aluminum

Hey there, ever found yourself staring at a shiny piece of aluminum, wondering how to get that perfect, clean cut? It might sound a bit niche, but trust me, picking the right blade for cutting aluminum is like having a secret superpower. It’s not just about making a cut; it’s about making a statement.

Think of it like this: you wouldn't use a butter knife to saw down a tree, right? The same principle applies to aluminum. Using the wrong tool can lead to a messy, jagged edge. That’s not the look we’re going for when we’re aiming for that smooth, professional finish.

So, what’s the magic key? It all comes down to the teeth of the blade. This is where the real fun begins! The number of teeth, their shape, and the material they’re made from all play a super important role. It's a bit like a puzzle, and finding the perfect fit is incredibly satisfying.

Let's dive into the star of the show: the carbide-tipped blade. This is your go-to hero for all things aluminum. Why carbide, you ask? Because it’s tough! It can handle the job without getting all bent out of shape. It’s like bringing a superhero to a minor skirmish.

Now, let's talk teeth count. For aluminum, you generally want a blade with a higher tooth count. This means more little sharp bits are doing the work. More teeth mean a smoother cut. It's like having a whole team of tiny, efficient workers instead of just a few struggling ones.

Imagine a blade with fewer teeth. It’s going to grab and rip, leaving you with a rough, uneven edge. Not exactly what you want when you’re aiming for that sleek, factory-fresh look. Nobody wants their aluminum project to look like it lost a fight!

But with a high-tooth-count blade, each tooth takes a smaller bite. This makes the cutting process much cleaner and more controlled. It’s all about finesse, not brute force. It’s the difference between a gentle whisper and a loud, obnoxious shout.

The gullet of the blade also matters. This is the space between the teeth. For softer metals like aluminum, you want gullets that are not too deep. This helps prevent the aluminum chips from clogging up the blade. A clogged blade is an unhappy blade, and an unhappy blade makes for a frustrating project.

When aluminum heats up while you’re cutting, it can get a bit sticky. If the gullets are too deep, those sticky bits can get stuck there. Then, your blade starts to struggle, and you’re left with a mess. It’s like trying to walk through mud with heavy boots!

A shallower gullet allows the chips to escape more easily. This keeps the blade running smoothly. It’s like having a clear path to walk on. You can just glide through the material.

Another thing to consider is the hook angle of the teeth. This refers to the angle at which the teeth are set. For aluminum, you want teeth with a positive hook angle. This helps the teeth to "grab" the aluminum and pull it into the cut effectively.

![Top 5 Best Blades for Cutting Aluminum [January 2025 Review] - MetalProfy](https://metalprofy.nyc3.cdn.digitaloceanspaces.com/wp-content/uploads/2020/10/best-blades-for-cutting-aluminum3.png)

Think of it like a tiny, sharp hook designed to snag the metal. This positive angle makes the cutting action more aggressive, but in a good way! It helps to efficiently remove material without putting too much stress on the blade or the material itself.

So, you're looking for a carbide-tipped blade with a high tooth count and a positive hook angle. This combination is the dream team for cutting aluminum. It’s like having a perfectly matched set of tools that work in harmony.

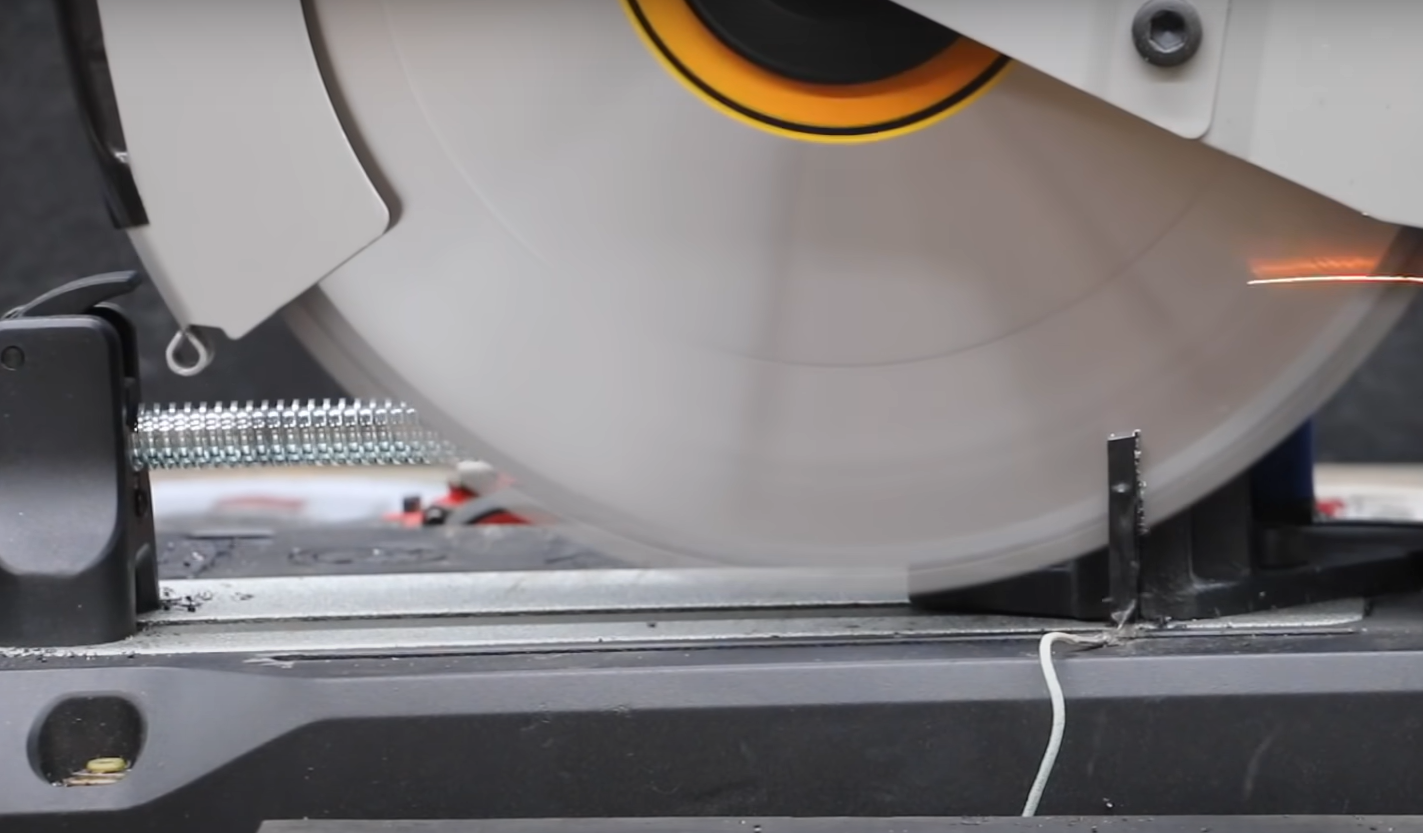

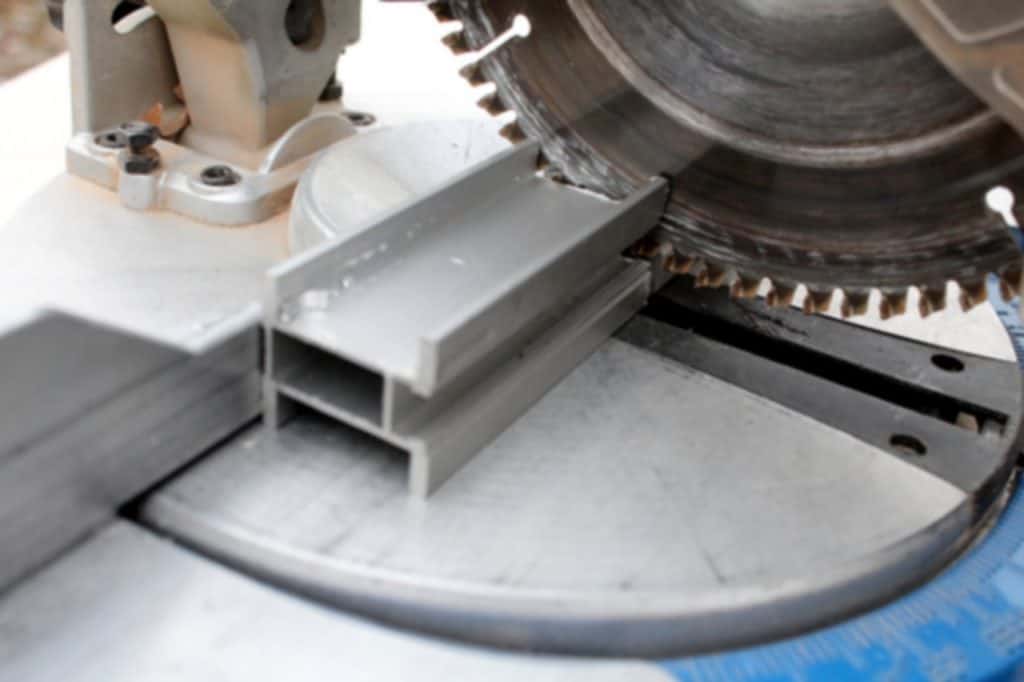

What kind of saw should you use? For smaller projects, a circular saw is a great option. Just make sure you’re using the right blade, of course. For bigger jobs, a miter saw or a table saw can also be used, again, with the correct blade.

Some people even use jigsaws with specific blades for curves, but that’s a whole other adventure! The key is matching the saw’s power and speed to the blade's capabilities.

Now, what about those alternative blades? You might see blades designed for wood, and some can cut metal, but they’re not ideal for aluminum. Wood blades often have fewer teeth and a different tooth shape. They’re designed for a different kind of material.

Using a wood blade on aluminum can lead to overheating, melting, and a really rough cut. You might even damage your saw or the blade itself. It’s a recipe for a frustrating and potentially dangerous situation. Stick to the specialized blades for the best results.

There are also abrasive blades, which are common for cutting metal. However, these create a lot of dust and heat. They're more like grinding than cutting, and they don't give you that clean, smooth edge you're after with aluminum.

The real joy comes from seeing that clean, precise cut. It’s almost mesmerizing to watch the blade glide through the metal, leaving behind a perfect edge. It's that moment of satisfaction when your project looks exactly how you envisioned it.

It’s about making your aluminum projects shine. Whether you're building something for your home, crafting a piece of art, or working on a DIY project, the right blade makes all the difference. It elevates your work from good to great.

Think of the possibilities! You can create beautiful, sleek designs with perfectly cut aluminum. Imagine crafting custom shelves, unique signs, or even parts for a model. The precision you get with the right blade opens up a world of creative potential.

It’s more than just cutting metal; it’s about the craft. It’s about the satisfaction of using the right tool for the job and seeing the beautiful results. It’s a small detail that makes a huge impact on the final outcome.

So next time you’re about to cut some aluminum, remember the magic words: carbide-tipped, high tooth count, positive hook angle. It might sound technical, but it's the secret to a truly impressive cut. It’s your ticket to that smooth, clean finish that makes your projects stand out.

Don't be afraid to experiment (safely, of course!) and see the difference for yourself. You might just find a new favorite tool and a new level of satisfaction in your DIY adventures. Happy cutting!