Drill Bits For Drilling Steel

Hey there, fellow DIY enthusiast! So, you're looking to conquer the mighty beast that is steel with your trusty drill? Awesome! Drilling into steel can sound a bit intimidating, like you're about to wrestle a metal dragon. But don't sweat it! It's totally doable, and with the right drill bits, it’s more like a polite handshake with a shiny piece of metal than a full-on brawl.

Think of drill bits as the tiny, but mighty, heroes of your drilling adventure. They’re the ones doing all the hard work, slicing and dicing through that tough stuff. And when it comes to steel, not just any old bit will do. You wouldn't wear flip-flops to climb Mount Everest, right? Same principle applies here!

So, let's dive into the wonderful world of drill bits designed specifically for steel. We'll keep it light, easy, and hopefully, you'll walk away feeling like a drill bit guru. Or at least, someone who knows not to grab a wood bit for their steel project. Baby steps!

The Usual Suspects: What Makes a Steel-Friendly Bit?

Alright, first things first. What’s the secret sauce? Why are some drill bits better for steel than others? It all comes down to a few key things:

Material Matters (A Lot!)

This is where the magic happens, folks. For steel, you want bits made from super-hardened materials. The most common and, frankly, the most effective players in this arena are:

- High-Speed Steel (HSS): This is your everyday, go-to guy. Think of it as the reliable workhorse of the drill bit world. HSS bits are great for general-purpose drilling in steel, especially softer steels. They’re tough, they can handle the heat generated during drilling (more on that later!), and they won't break the bank. They’re like the comfortable jeans of your toolbox – always a good choice.

- Cobalt Steel (HSS Co): Now we're stepping it up a notch! Cobalt bits are essentially HSS bits with a good dose of cobalt added. This makes them even tougher and more heat-resistant. If you're drilling harder steels, stainless steel, or doing a lot of drilling, cobalt is your best friend. They’re the sturdy hiking boots of your collection – ready for a tougher trek. They might cost a little more, but trust me, they're worth it when you're battling stubborn metal.

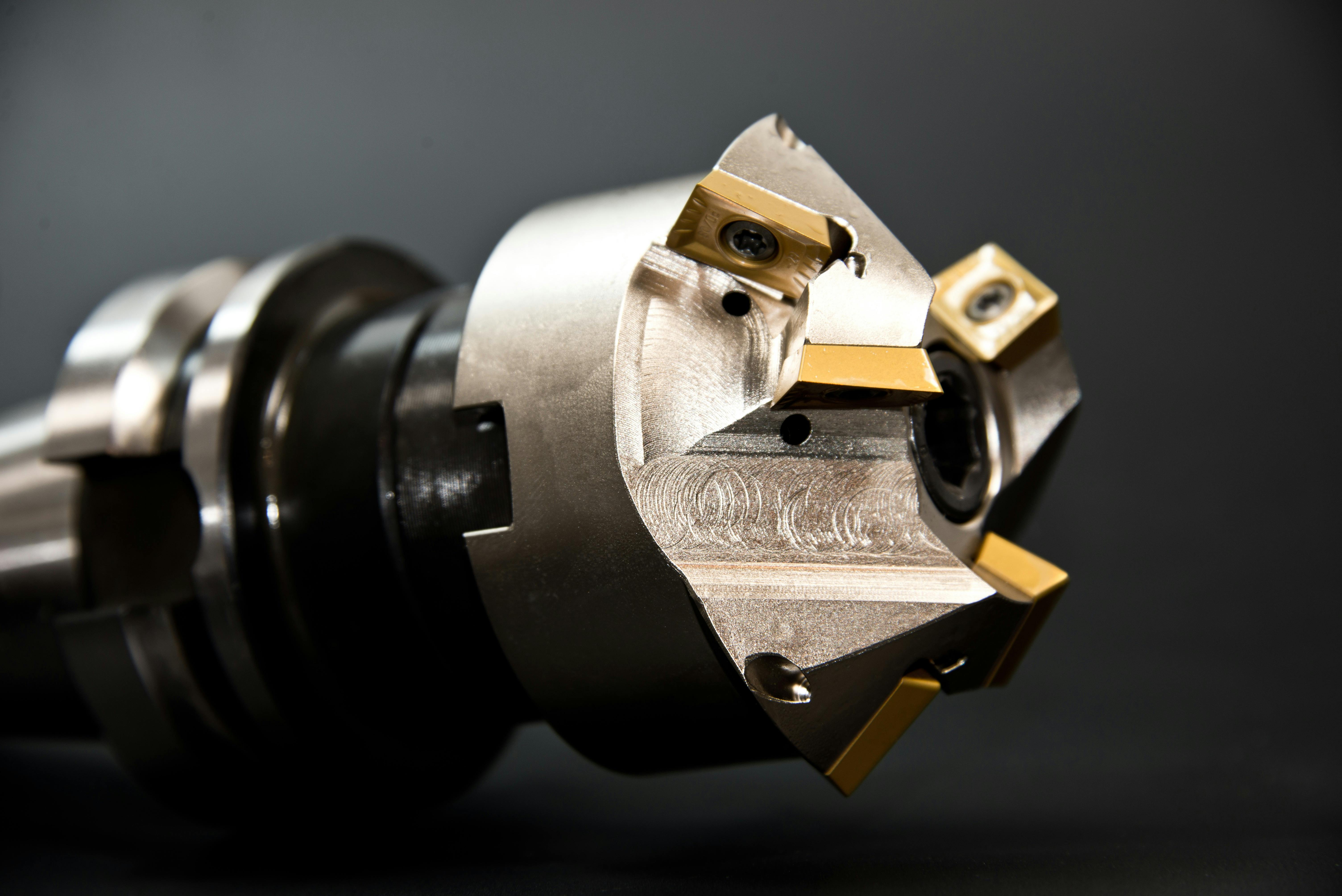

- Carbide (Solid Carbide or Carbide Tipped): These are the heavyweights. Solid carbide bits are incredibly hard and wear-resistant. Carbide-tipped bits have carbide brazed onto a steel shank. These are for the really tough jobs, like drilling through hardened steel or very abrasive materials. They can handle extreme temperatures and can drill much faster. However, they are also more brittle, so you need to be careful not to put too much sideways pressure on them. Think of these as the specialized climbing gear for the most extreme peaks.

Generally, for most home projects and even some light professional work, HSS bits will get the job done. But if you’re hitting something really tough or drilling a lot, upgrading to cobalt is a smart move. And for the truly hardcore stuff? That’s when you bring out the carbide cavalry.

Coatings: The Shiny Armor

Even good bits can get a little extra boost from special coatings. These aren't just for looks (though a shiny bit is kind of cool, admit it!). Coatings help bits:

- Reduce friction: This means less heat and easier drilling.

- Increase hardness: Making them even more durable.

- Prevent rust: Because nobody likes a rusty drill bit.

Some common coatings you'll see include:

- Black Oxide: This is a common and affordable coating. It helps with corrosion resistance and provides some lubrication. It's like a basic protective layer, giving your bit a bit of an edge.

- Titanium Nitride (TiN): This is a popular yellow-ish coating. It’s harder than black oxide and offers better heat resistance and lubricity. It makes the bit cut faster and last longer. Think of this as a nice, reliable shield.

- Titanium Aluminum Nitride (TiAlN): This fancy coating is usually purplish and is for even higher temperatures and harder materials than TiN. It's often found on bits designed for aggressive drilling or high-speed applications. This is your advanced, energy-shielding armor.

For drilling steel, especially if you’re using cobalt bits, coatings are a fantastic addition. They’re like giving your drill bit a superhero cape – makes it perform better and look cooler!

The Anatomy of a Steel-Drilling Champ: Key Features

Beyond the material and coatings, there are a couple of other bits (pun intended!) of information that can help you pick the right one:

The Point Angle

This is the angle at the very tip of the drill bit. For steel, you'll generally want a 118-degree point angle. This is a standard, general-purpose angle that works well for most metals. It provides a good balance of cutting action and stability.

If you're drilling very thin sheet metal, you might sometimes see bits with a sharper angle (like 90 degrees), but for general steel drilling, stick with 118 degrees. Think of it as the Goldilocks angle – not too steep, not too blunt, just right!

Flutes: The Chip Evacuators

These are the spiral grooves that run up the bit. Their main job is to clear away the metal chips (or swarf, as the pros call it) as you drill. Good flute design helps prevent the bit from overheating and getting jammed.

For steel, you generally want bits with deep, well-formed flutes. This allows the chips to escape easily, which is super important for keeping your bit cool and your drilling smooth. Imagine them as tiny conveyor belts whisking away the debris.

Web Thickness

This refers to the thickness of the metal in the center of the flutes. A bit with a thicker web is generally stronger and can handle more pressure. As a bit wears down, the web thickness can increase, which can make drilling harder. Some bits have a “thinning” at the tip to compensate for this.

Don't get too bogged down in this unless you're a real drill bit nerd. Just know that a well-constructed bit will have a decent web thickness for its size.

When to Use What: A Mini-Guide

So, you've got a steel project. What bit do you grab? Here’s a quick cheat sheet:

- Soft steel (like mild steel, structural steel): A good quality HSS drill bit, perhaps with a Black Oxide or Titanium coating, will do the trick.

- Harder steels (like some tool steels, or if you're drilling a lot): Definitely step up to a Cobalt drill bit. A Titanium Nitride (TiN) coating is a great bonus here.

- Very hard or hardened steel, or high-volume production drilling: This is where you’ll likely need Carbide drill bits.

It’s also worth mentioning left-hand drill bits. These drill in the opposite direction (counter-clockwise). Sometimes, when drilling into a stuck bolt, a left-hand bit can actually catch and unscrew the bolt as it drills! Pretty neat trick, eh?

Drilling Steel Like a Pro (Even If You're Just Pretending!)

Getting the right drill bit is only half the battle. Here are a few tips to make your steel-drilling experience smoother and safer:

Coolant is Your Friend!

This is a biggie! Steel generates a LOT of heat when you drill it. Heat is the enemy of your drill bit. It can make it dull quickly, and in extreme cases, can even cause it to break. So, use a cutting fluid or lubricant.

You can buy dedicated cutting fluids, or even use a bit of motor oil in a pinch. Apply it regularly to the drill bit and the workpiece. It’ll keep things cool, lubricated, and help those chips clear away nicely. Think of it as giving your bit a refreshing drink on a hot day!

Speed Demon? Not So Fast!

When drilling steel, you generally need to go slower than you would for wood or plastic. Too fast, and you’ll just generate excessive heat and make a mess. Experiment with different speeds, but err on the side of slower is better. Your drill motor (and your drill bit!) will thank you.

A good rule of thumb is that the harder the material, the slower you should drill. And the larger the drill bit, the slower you should drill.

Pressure: Gentle Does It

Apply steady, even pressure. Don't try to force the drill bit through the steel. Let the bit do the work. If you’re applying too much pressure, it’s a sign that your bit might be dull, you’re going too fast, or you need a more appropriate bit for the material.

A little bit of pressure is needed to make the bit cut, but it shouldn’t feel like you're wrestling a bear. Imagine you're guiding it, not forcing it.

Starting Strong: The Pilot Hole

For larger holes, or if you're drilling into thicker steel, it’s a great idea to drill a pilot hole first. Use a smaller drill bit to create a starting point. This helps prevent the larger bit from "walking" or wandering around the surface when you start drilling. It’s like giving yourself a clear path to follow.

Clamping Down: Safety First!

Always, always, always clamp your workpiece securely. Steel can grab and twist unexpectedly, especially if your drill bit gets bound up. A loose piece of metal can become a dangerous projectile. Use clamps, vices, or whatever you have to keep that steel firmly in place.

And wear your safety glasses! Those metal chips can fly. Seriously, don’t skip the safety gear. It’s not as glamorous as a fancy drill bit, but it’s way more important.

The Joy of the Hole

So there you have it! Drilling steel doesn't have to be a daunting task. With the right drill bits – whether they’re trusty HSS, robust Cobalt, or the mighty Carbide – and a few smart techniques, you can create clean, precise holes in metal like a seasoned pro.

Remember, each drill bit is designed with a purpose, and understanding a little about what makes them tick will make all the difference. Think of it as learning the secret handshake of the metalworking world. Soon you'll be confidently choosing the perfect bit for the job, and your projects will be that much easier and more satisfying.

The next time you look at a piece of steel and think, "Can I drill this?", the answer is a resounding YES! With the right tools and a little know-how, you've got this. So go forth, drill with confidence, and enjoy the sweet satisfaction of a job well done. Happy drilling, and may your holes be ever so straight!