Heavy Wall Telescoping Steel Tubing. 12L14 Steel Cold Finished Round Bar. A 36 Hot Rolled Steel. 1045 Turned-Ground-Polished Steel Shafting. Carpenter 158. 3/4" Diameter Carpenter 158 Round Bar. Copper. 110.

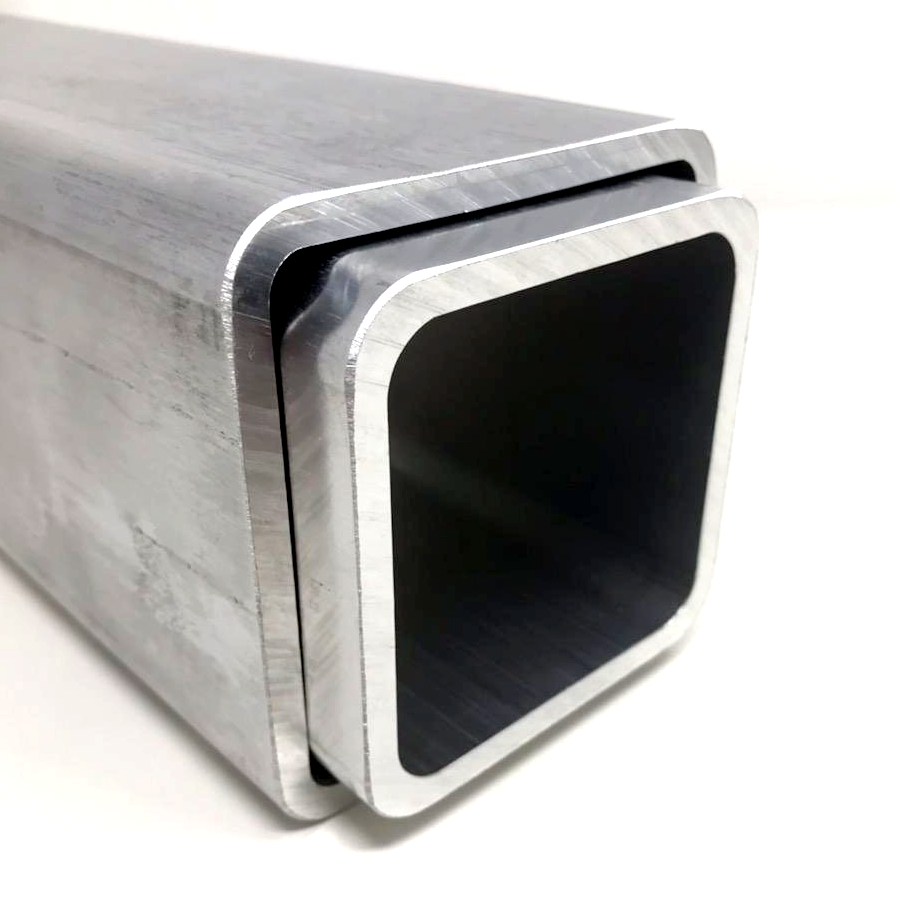

Heavy wall telescoping steel tubing is a type of tubing that is used in the construction and engineering industries. It is made from steel that has been shaped into a tube that has a larger diameter than standard steel tubing. The heavy wall telescoping steel tubing is designed to be used in applications that require a stronger and more durable tubing than the standard steel tubing.

The heavy wall telescoping steel tubing is made to be used in applications where the tubing needs to be able to withstand higher levels of pressure and stress. This type of tubing is often used in the construction of bridges, buildings, and other large structures. In addition, it is also used in the manufacturing of heavy machinery and equipment.

The heavy wall telescoping steel tubing comes in various sizes and shapes. It is also available in different thicknesses, ranging from thin wall to heavy wall. The dimensions and thickness of the tubing will depend on the application for which it is being used.

When installing the heavy wall telescoping steel tubing, it is important to ensure that it is properly aligned. This can be done by using a level and a straight edge. It is also important to ensure that the tubing is secured to the structure with the appropriate fasteners. If the tubing is not properly aligned, it could cause the structure to be unstable.

In order to cut the heavy wall telescoping steel tubing, it is necessary to use a saw or other cutting tool. It is important to use a saw that is designed for cutting steel and that is equipped with a carbide-tipped blade. This will ensure that the tubing is cut properly and that it is cut to the correct size.

When welding the heavy wall telescoping steel tubing, it is important to use the correct welding process. It is recommended to use a MIG or TIG welding process when welding the tubing. It is also important to ensure that the welding is done properly and that the tubing is sealed properly to prevent leaks.

The heavy wall telescoping steel tubing is a great choice for applications that require a strong and durable tubing. It is important to ensure that the tubing is properly installed and secured, and that it is cut and welded correctly in order to ensure that it will provide the necessary support and strength for the structure that it is being used for.

Tips For Telescoping Tube | Metal Supermarkets

In this video blog, we review our top tips for telescoping tube. If you need tube for your next project, visit: metalsupermarkets.com/

Telescoping Tubing. Many factors need to be considered before a successful telescoping application is achieved, including dimensional, wall, and corner radii tolerances along., Heavy Wall Telescoping Steel Tubing.