Peristaltic Pump Tubing Chemical Compatibility

Hey there, fellow adventurers in the land of fluids and fantastic contraptions! Ever found yourself staring at a peristaltic pump, its little rollers doing their rhythmic dance, and wondered, "What's actually going on in there?" More importantly, have you ever thought about the unsung hero of this whole operation: the tubing?

Now, I know what you might be thinking. "Tubing? Chemical compatibility? Sounds… well, a little dry, doesn't it?" But hold your horses, my friends! Because understanding this seemingly niche topic can actually unlock a whole new level of fun and efficiency in your projects, whatever they may be. Think of it as unlocking a secret level in your favorite game, but with less pixelated dragons and more perfectly pumped liquids!

The Humble Hero: Peristaltic Pump Tubing

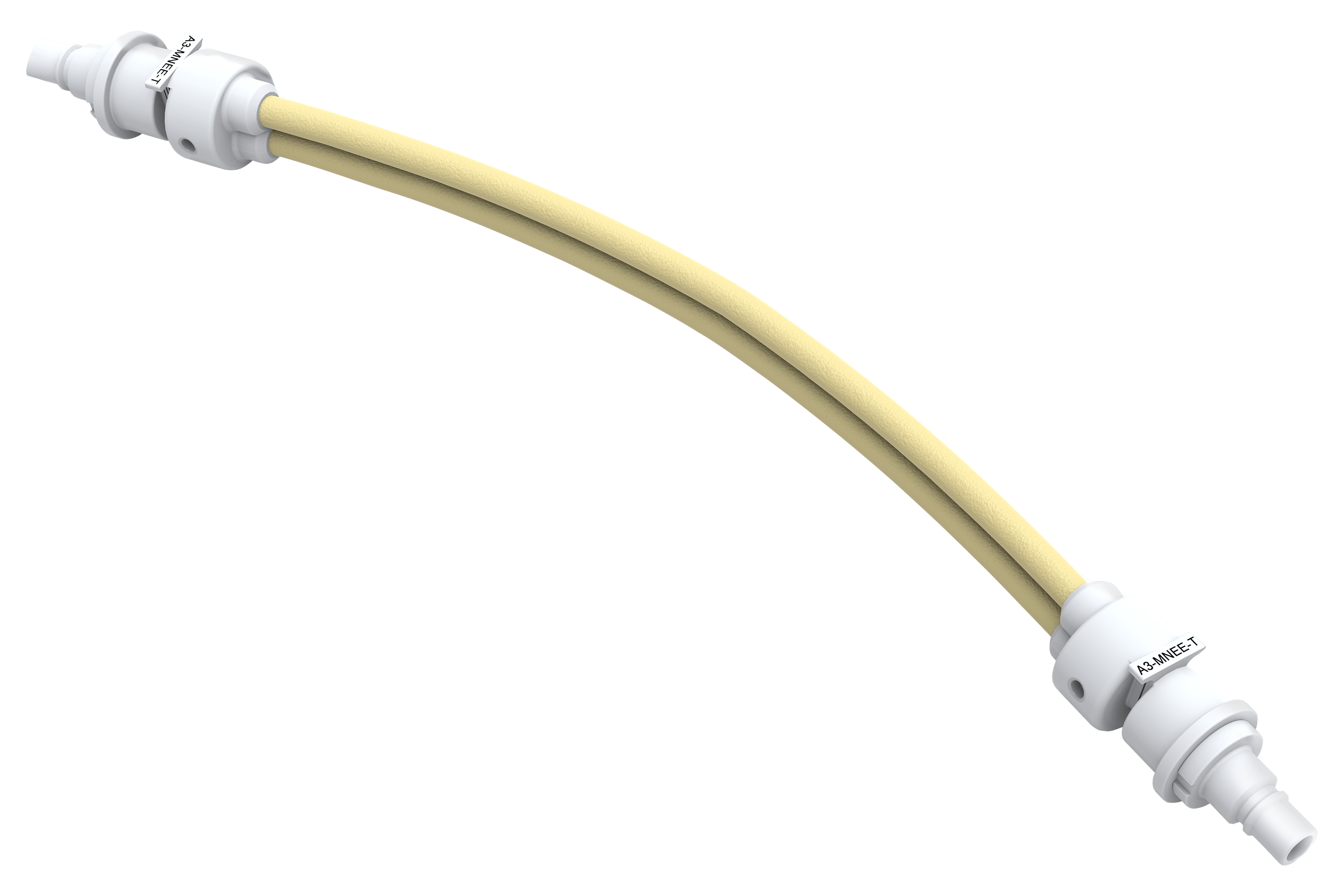

Let's talk about our star player: peristaltic pump tubing. These flexible tubes are the lifeblood (or should I say, the fluid-blood?) of your peristaltic pump. They're the ones getting squeezed, released, squeezed, released – a constant, gentle massage that pushes your precious fluids along. Pretty neat, right? They work on a principle called peristalsis, which, if you're feeling fancy, is the same wave-like muscle contractions that move food through your digestive system. So, in a way, your pump is giving your liquid a little internal spa treatment!

But here’s the catch, and it’s a rather important one. Not all tubing is created equal. And when we're talking about pumping chemicals, be they simple water or something a bit more… zesty, the relationship between your tubing and those chemicals is crucial. It's like a dance – if you’ve got the wrong dance partner, things can get… messy. Or worse!

The Dance of Molecules: Chemical Compatibility Explained

So, what exactly is "chemical compatibility"? Simply put, it’s about whether your chosen tubing material is going to play nicely with the chemical you're trying to pump. Will it stay strong and flexible, or will it start to break down, swell up, or even leach unwanted substances into your fluid? Think of it as a compatibility test for your molecules. Are they friends, or are they destined for a dramatic breakup?

If your tubing isn't compatible, you're looking at a few potential party fouls:

- Swelling: The chemical can seep into the tubing material, causing it to swell like a balloon that's had one too many fizzy drinks. This can mess with the pump's accuracy and even damage the tubing.

- Hardening: On the flip side, some chemicals can actually dry out the tubing, making it brittle and prone to cracking. Imagine trying to bend a stale pretzel – not ideal!

- Leaching: This is a big one, especially if you’re pumping something for consumption or a sensitive application. The chemical can break down the tubing material, and bits of the tubing can end up in your fluid. Yuck!

- Degradation: The ultimate betrayal! The chemical can completely break down the tubing, leading to leaks, pump failure, and a general sense of despair.

Nobody wants their meticulously planned experiment or their creative concoction to go sideways because of a little tubing misstep. It’s like packing for a picnic and realizing you’ve brought salt instead of sugar. We've all been there, right? But with chemical compatibility, the stakes can be a bit higher than a slightly less sweet jam!

Decoding the Alphabet Soup: Common Tubing Materials

Okay, so we need to pick the right tubing. But with so many materials out there, where do you even start? Don't worry, we're not going to dive into a full-on chemistry lecture. We'll just touch on some of the usual suspects:

- Silicone: This is a popular choice for many applications. It's generally flexible, has a good temperature range, and is often biocompatible. It plays nicely with water, some dilute acids and bases, and a lot of common solvents. Think of it as the friendly, go-with-the-flow material of the tubing world.

- PVC (Polyvinyl Chloride): Another workhorse. It’s often cost-effective and quite durable. However, its compatibility can vary depending on plasticizers and the specific chemical. It's good for water, many oils, and some acids.

- Tygon®: This is actually a brand name for a range of different tubing formulations, so it’s a bit like saying "car" – there are many types! Some Tygon formulations are excellent for aggressive chemicals, while others are designed for food and beverage applications. Always check the specific Tygon series for compatibility. It's like knowing your friend has a specific talent – you need to know which talent!

- Viton®: If you're dealing with really tough chemicals, especially hydrocarbons, oils, and strong acids, Viton® might be your superhero. It's known for its excellent chemical resistance but can be less flexible and more expensive.

- Santoprene®: This is a thermoplastic vulcanizate (TPV) and offers a good balance of flexibility and chemical resistance, often performing well with many acids, bases, and solvents. It's like the versatile athlete of the tubing family.

The key takeaway here is that there’s no single "best" tubing for everything. It’s all about the match. It’s like finding the perfect pair of shoes – you wouldn’t wear flip-flops to climb a mountain, would you? (Unless you're really daring, but let's not go there!).

Where the Magic Happens: Finding Your Compatibility Chart

So, how do you actually find out what works with what? Thankfully, the manufacturers of tubing and chemicals are usually quite helpful. Most reputable tubing suppliers will have detailed chemical compatibility charts available on their websites. These charts are your treasure maps!

You simply look up the chemical you're using, and it will tell you which tubing materials are recommended, which are suitable with limitations, and which to absolutely avoid. It’s usually presented in a clear, table format. Think of it as a cheat sheet for your fluid-handling adventures!

Sometimes, you might need to dig a little deeper. If you're working with a particularly obscure chemical or a unique blend, don't be afraid to reach out to the tubing manufacturer directly. They often have technical experts who can help you make the right choice. It’s like asking a librarian for a specific book – they know where to find it!

Making Life More Fun (Yes, Really!)

Now, you might still be asking, "How does knowing about tubing make my life fun?" Well, let me tell you! When you get chemical compatibility right, your peristaltic pump works smoother, it lasts longer, and you avoid those frustrating leaks and failures. This means less time spent troubleshooting and more time spent on the exciting parts of your project – the creation, the experimentation, the discovery!

Imagine this: you’re setting up a cool DIY brewing system, and your pump is reliably dispensing the perfect amount of sanitizer without breaking down. Or you’re working on a science project with your kids, and the colorful liquid is flowing perfectly, making the experiment a visual delight. Or perhaps you're a small business owner, and your production line is humming along without a hitch, thanks to reliable fluid transfer. That’s the quiet joy of a well-chosen component!

It’s about enabling your creativity. It’s about ensuring your hard work isn’t undone by a simple, preventable issue. When your equipment works with you, instead of against you, the possibilities feel endless. You can focus on the bigger picture, on the innovations you want to bring to life, on the sheer pleasure of building and making things.

An Inspiring Endeavor

So, the next time you’re looking at a peristaltic pump, remember the unsung hero: the tubing. And remember that understanding its chemical compatibility isn't just a technical detail; it's a key to unlocking smoother operations, more successful projects, and ultimately, more enjoyment in whatever you’re doing. It's a small piece of knowledge that can have a big, positive impact.

Don't be intimidated by the jargon. Embrace the learning! Think of it as an invitation to explore the fascinating world of materials science and fluid dynamics, even if it's just for your own personal projects. The world of pumps and tubing might seem small, but it’s an essential part of so many amazing things. So, dive in, do your research, and let the right tubing help you bring your fluidic dreams to life!