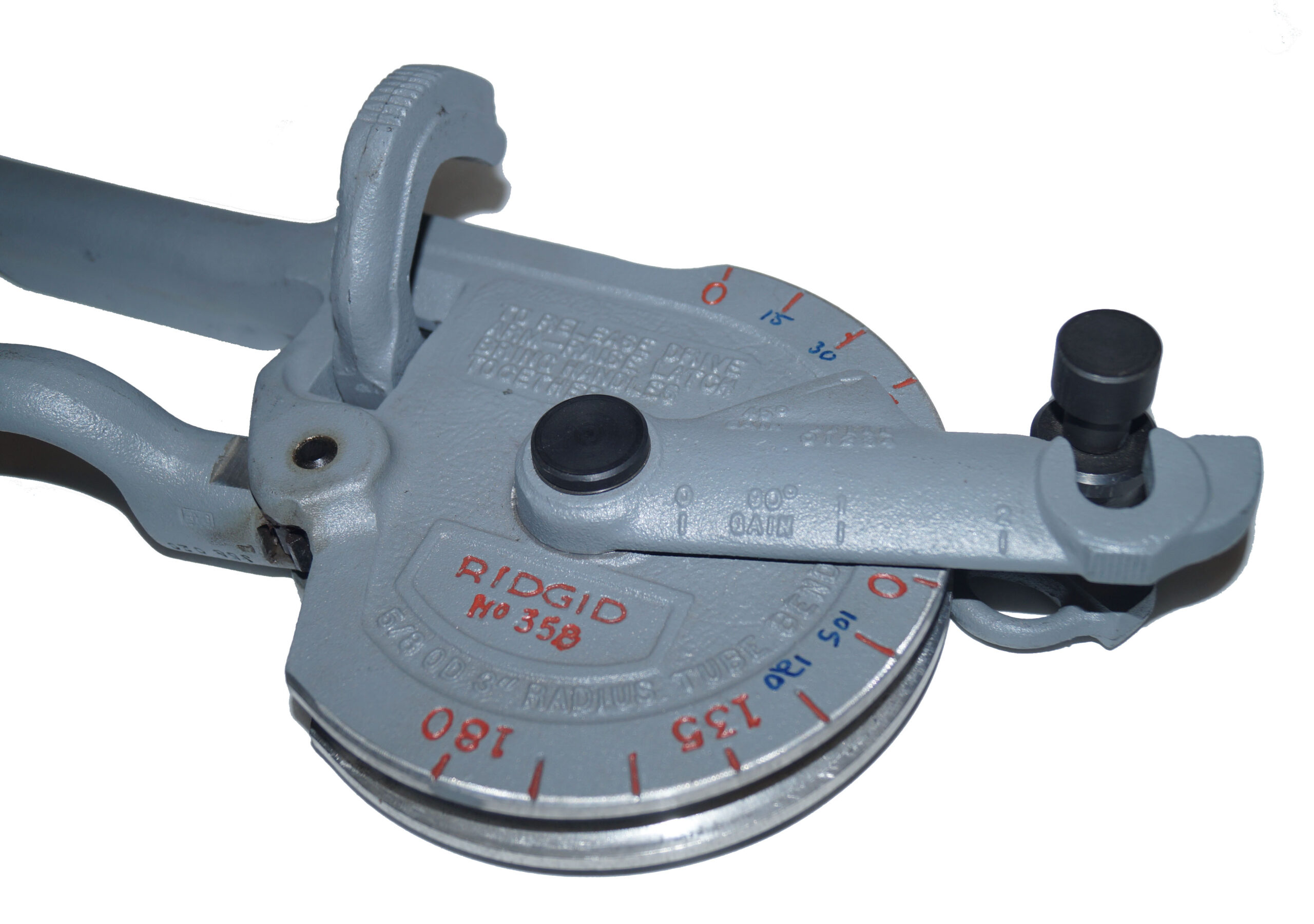

Ridgid 5 8 Tubing Bender

Ever found yourself looking at a piece of tubing and wondering how those neat, precise bends come to be? It’s a question that might spark curiosity for anyone who’s ever tackled a DIY project, admired intricate plumbing, or even just noticed the smooth curves in everyday objects. Well, wonder no more! Today, we’re diving into the fascinating world of the Ridgid 5/8" Tubing Bender – a tool that’s as practical as it is satisfying to use.

So, what exactly is this contraption, and why should you care? At its core, a tubing bender is designed to do one thing incredibly well: bend metal tubing without crimping, kinking, or distorting its shape. Think of it like giving metal a controlled hug, shaping it precisely where you want it. The Ridgid 5/8" model, specifically, is built for tubes with a 5/8-inch outer diameter, making it a go-to for many common plumbing, refrigeration, and HVAC applications. The magic lies in its robust construction and carefully engineered dies that guide the tube through a perfect arc. This ensures a smooth, consistent bend every single time, which is crucial for fluid flow and structural integrity. No more wrestling with pipes, hoping for the best!

The benefits are pretty straightforward: precision and efficiency. Instead of cutting and soldering multiple pieces to create an angle, you can bend a single length of tubing. This saves time, reduces the number of potential leak points, and often results in a cleaner, more professional-looking finish. For anyone working on a project that requires custom tube runs, this tool is an absolute game-changer. It’s the difference between a jury-rigged solution and a beautifully executed piece of engineering.

Where might you encounter this kind of precision bending? Well, beyond the obvious professional trades, think about educational settings. In vocational schools, students learning about mechanics, plumbing, or even automotive repair will use tools like the Ridgid bender to understand the principles of working with metal. Imagine a high school physics class demonstrating fluid dynamics with custom-built systems, or a shop class creating a unique piece of furniture with metal accents. In daily life, you might see its handiwork in the sleek lines of a custom motorcycle exhaust, the intricate copper piping in a home’s air conditioning system, or even the perfectly angled supports for a shelf. It's all about creating functional art from simple materials.

Curious to explore it further? You don’t need to be a master plumber to appreciate the concept. If you have access to some scrap 5/8" soft copper or aluminum tubing (check local hardware stores or scrap yards!), you can often find benders for rent or even purchase an older, used model to experiment with. Many online tutorials demonstrate the basic operation – how to set up the tube, engage the handles, and apply steady pressure. It’s a hands-on way to understand the principles of leverage and material deformation. The satisfying click and smooth movement as the tube takes shape is surprisingly rewarding. So, next time you see a well-bent tube, you'll know there's a little bit of thoughtful engineering, and perhaps a Ridgid bender, behind that smooth curve.