Telescopic Square Tube Uk

So, picture this: I was helping my mate Dave with his shed extension the other weekend. Dave, bless his cotton socks, isn't exactly what you'd call a DIY guru. More like a "let's give it a go and see what happens" kind of guy. Anyway, we were wrestling with this rather wonky frame, and he’s muttering about how everything seems to be a different size. You know, that feeling when you're trying to make two things meet, and they just… won't? It's like a cosmic joke, but with wood and nails.

He’d bought some pre-cut timber, thinking he was being all efficient. But then, as we were trying to secure a crucial support beam, it became glaringly obvious that the "standard" lengths weren't quite standard enough. We spent a good hour fiddling, measuring, re-measuring, and generally questioning our life choices. That’s when it hit me – what if there was a better way? A way to have something that could adapt, that could grow or shrink to fit the need? And that, my friends, is how I stumbled down the rabbit hole of the telescopic square tube.

The Humble Heroes of Adjustable Structures

Now, I know what you’re thinking. "Telescopic square tube? Sounds… industrial." And yeah, it does. It’s not exactly glamorous, is it? It’s not a fancy new gadget that’ll make your coffee for you. But let me tell you, these things are the unsung heroes of the construction and fabrication world. They’re like the duct tape of the structural world – you might not always see them, but when you need them, oh boy, do you need them.

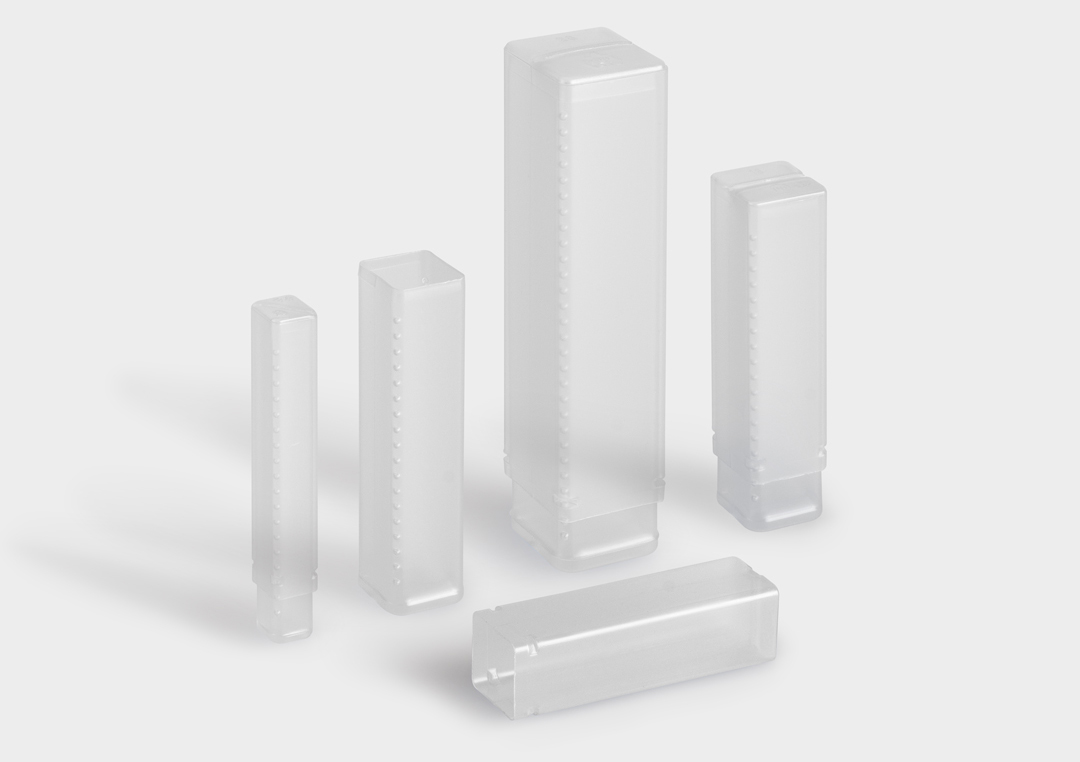

Basically, a telescopic square tube is just that: a series of nested square tubes that can slide in and out of each other. Think of it like a really sturdy, metal set of Russian nesting dolls. You’ve got an outer tube, and then one or more smaller tubes that fit snugly inside. Slide them out, and you get a longer length. Slide them in, and you get a shorter, more compact one. Simple, right? But the implications? Far from simple. They’re downright clever.

Why You Might Actually Care About These Tubes

Okay, so maybe you’re not building a shed this weekend. Maybe your DIY ambitions extend to assembling IKEA furniture (and let’s be honest, that’s an adventure in itself). But even then, understanding the principles behind adjustable structures can be incredibly useful. And telescopic square tubes are a prime example of that.

The primary benefit, as you’ve probably guessed, is adjustability. This is the big one. Instead of having to order a specific length of steel or aluminium, or cutting something down to size (which, let’s face it, often results in a less-than-perfect finish and a lot of wasted material), you can use a telescopic tube. You can extend it to the exact length you need. This saves you time, it saves you money, and it significantly reduces the margin for error. Remember Dave’s wonky frame? A telescopic solution there would have been a dream.

Think about it: if you’re building something that needs to be a certain size now, but might need to be slightly longer or shorter later, a telescopic tube is your best friend. It offers flexibility that static materials just can't match. This is why they're so popular in industries where precise, but also adaptable, structures are key.

Where Do These Things Show Up? (You’d Be Surprised!)

You might think they’re niche, but honestly, once you start looking, you'll see them everywhere. Or, at least, the principles of them. Think about:

- Scaffolding: Ever seen scaffolding that seems to magically adjust to different building heights? Yep, that’s often down to adjustable components, and telescopic tubes are a common feature. They allow for quick and easy height and width adjustments, making complex structures much more manageable.

- Exhibition stands and displays: Setting up for a trade show? Need to adapt your booth to fit a different sized space? Telescopic tubes are brilliant for creating frames for signage, display units, and even modular stands that can be reconfigured endlessly. Imagine how much easier it would be to pack and transport a stand that can collapse down neatly!

- Adjustable workbenches and tables: Need a workbench at a specific height for a project, but then want it lower for storage? Telescopic legs are the answer. They provide sturdy support and easy height adjustment.

- Support structures for various industries: From agriculture to manufacturing, any situation requiring adjustable supports or frames can benefit. Think about adjustable shelving, conveyor systems that need to be slightly repositioned, or even supports for temporary structures.

- Furniture: Okay, maybe not your average IKEA flat-pack, but some higher-end or custom furniture pieces might use telescopic elements for adjustable height or length. Think of those fancy adjustable desks or even some types of beds.

It’s this versatility that makes them so appealing. They aren’t just for one specific job; they can be adapted to a surprisingly wide range of applications. It’s like having a chameleon in your toolbox. Not literally, of course. That would be weird. And probably not very structural.

The Magic of the Fit: How Do They Stay Put?

So, if they just slide in and out, how do they actually stay in place when you want them to? This is where the engineering bit gets interesting. There are a few common mechanisms:

- Set screws or grub screws: This is probably the most straightforward. There’s a small hole drilled through the outer tube, and a corresponding hole in the inner tube. A screw is then tightened through the outer tube, digging into the inner tube and creating friction. It’s like a tiny, very determined clamp. You loosen the screw to adjust, and tighten it to lock. Simple, effective.

- Spring plungers or detent pins: These are a bit more sophisticated. You’ll often see these with pre-drilled holes at regular intervals on the inner tube. A spring-loaded pin (or plunger) sits in the outer tube, and when you align it with a hole on the inner tube, it pops in and locks the tubes in position. You just pull the pin to release and slide. These are great for quick adjustments where you need to lock at specific increments. Think of them as very precise, spring-loaded buttons.

- Clamps or levers: Some heavier-duty applications might use external clamps or levers that apply pressure to the inner tube, effectively gripping it from the outside. This provides a very strong locking mechanism.

The choice of locking mechanism often depends on the load the tube will bear, how often it needs to be adjusted, and the desired level of precision. For my mate Dave’s shed, a simple set screw would have probably done the trick. But for something supporting a lot of weight, you'd want something a bit more robust.

The ‘UK’ Part of the Equation

Now, let's bring it back to the UK. When you're looking for these in the UK, you're going to find a whole host of suppliers. From the big DIY superstores (though they might have a more limited range) to specialised metal stockists and online retailers. The term "telescopic square tube UK" will likely bring up a whole load of results.

You'll find them made from different materials. Steel is common for strength and durability, often galvanised for rust resistance – very important in our lovely British weather! Aluminium is lighter and also rust-resistant, making it a good choice for applications where weight is a factor, like exhibition stands or portable structures.

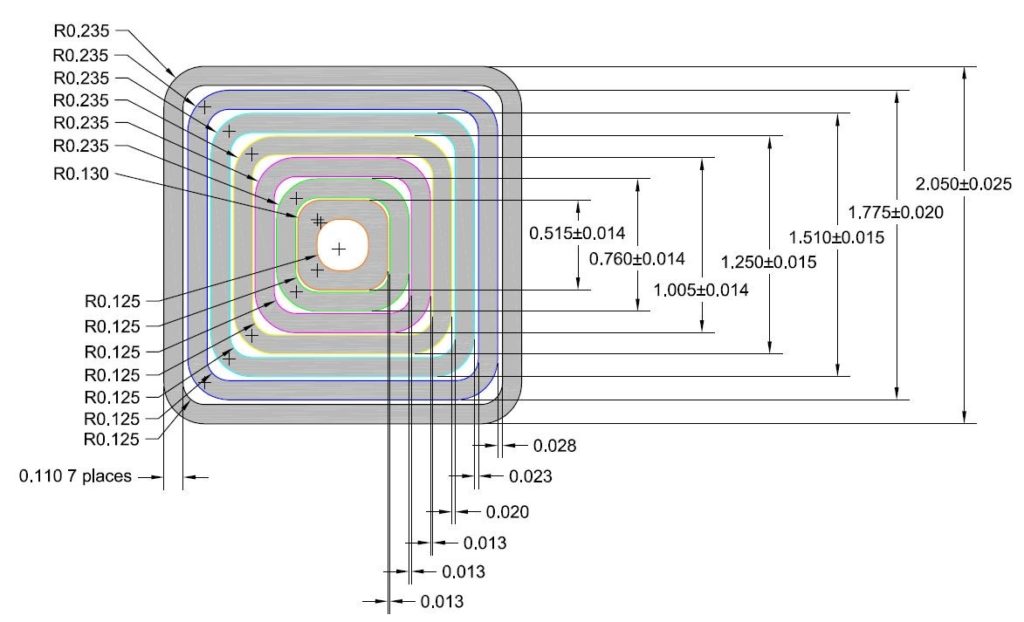

The sizes can vary wildly, too. You'll find everything from small, lightweight tubes for model making or delicate projects, to chunky, heavy-duty ones for industrial applications. The wall thickness is also a crucial factor; a thicker wall means a stronger tube, capable of handling more weight. So, when you're browsing for "telescopic square tube UK," make sure you're paying attention to the specifications:

- Dimensions: Outer tube size and inner tube size (and how much overlap there is).

- Length: Minimum extended length and maximum extended length.

- Material: Steel, aluminium, stainless steel, etc.

- Wall Thickness: How thick the metal is.

- Load Capacity: How much weight it can safely support.

- Locking Mechanism: How it’s designed to stay in place.

It might sound like a lot of detail for what is essentially a sliding tube, but when you’re building something, the details are everything. One wrong spec, and your carefully constructed project could end up looking more like Dave’s shed – a testament to good intentions and slightly wonky execution.

A Word to the Wise (From Someone Who Knows a Bit Now)

If you're embarking on a project that requires any kind of adjustable structural element, seriously, give telescopic square tubes some consideration. Don't just dismiss them as being too "industrial" or "boring." They are incredibly practical. They solve problems. They make life easier. And in the world of DIY and fabrication, anything that makes life easier is worth its weight in gold. Or, you know, in galvanised steel.

Think about it: the next time you're wrestling with something that just doesn't quite fit, or you're faced with the dreaded "cut it yourself" scenario, remember the humble telescopic square tube. It’s the adaptable, flexible, and often overlooked solution that could save you a lot of headaches. And who doesn't want to save a few headaches? I know I do.

So, go forth and explore! Look up "telescopic square tube UK" and see what you find. You might just be surprised at the possibilities. And who knows, maybe your next project will be so perfectly adjusted, it'll make Dave weep with envy. Or at least, make it a lot less wobbly. And that, my friends, is a win in my book.