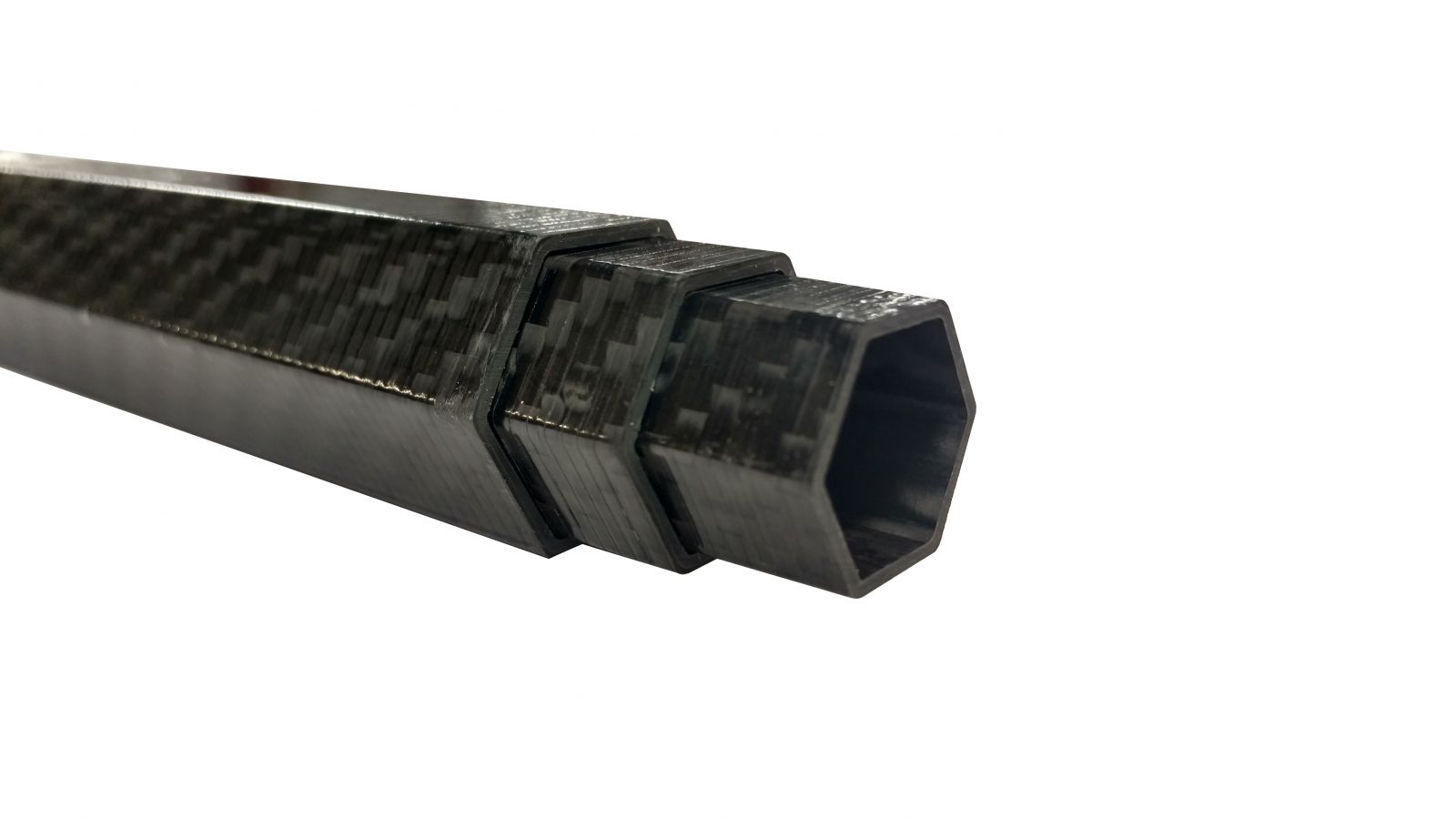

Telescoping Carbon Fiber Tubes. Elbridge, NY (PRWEB) May 05, 2016. Dragonplate has recently released a telescoping tube clamp system that provides a strong, yet easy to use method for. Our carbon fiber tubes are extremely durable and impact-resistant, capable of withstanding accidental impacts without compromising the structural integrity of the tube. This makes. Telescoping Carbon Tubing Telescoping Tubes Excellent Telescoping Tubes Build Your Own Telescoping Systems + Versatility = Virtually Limitless Applications Rock West.

Telescoping carbon fiber tubes are one of the most widely used materials in the aerospace and automotive industries. Carbon fiber is a strong and lightweight material that is often used to create components for these industries. Telescoping carbon fiber tubes are created by wrapping multiple layers of carbon fiber cloth around a mandrel. This creates a tube that is strong, lightweight, and flexible. The flexibility of the tube allows it to be extended and retracted as needed. This makes it ideal for applications such as telescoping antennas, robotic arms, and other applications that require a flexible and adjustable tube.

The process of creating a telescoping carbon fiber tube begins with selecting the appropriate carbon fiber cloth for the application. The cloth must be chosen for its strength, flexibility, and other characteristics that are required for the application. Once the carbon fiber cloth is selected, it is cut into strips that are the same length as the desired tube length. The strips are then wrapped around the mandrel, with each layer being slightly longer than the one before it. This creates a tube that is strong and flexible and can be extended and retracted as needed.

The next step in creating a telescoping carbon fiber tube is to apply an adhesive to the layers of cloth. This adhesive helps to bond the layers together and create a strong and durable tube. The adhesive can be either a two-part epoxy or a resin-based adhesive. Once the adhesive has been applied, the tube is then heated to cure the adhesive. This ensures a strong and durable bond between the layers.

Once the adhesive has been applied and cured, the final step is to add any additional components that are needed for the application. This could include end caps, connectors, or other components that may be needed. Once the components are added, the tube is ready to be used in the application.

Benefits of Telescoping Carbon Fiber Tubes

There are many benefits to using telescoping carbon fiber tubes. The most notable benefit is the strength and flexibility of the material. Carbon fiber is known for its strength, which makes it ideal for applications where strength and durability are needed. The flexibility of the material also allows for easy adjustment and customization of the tube. This makes it ideal for applications such as telescoping antennas or robotic arms.

The lightweight nature of carbon fiber also makes it ideal for applications where weight is a factor. Telescoping carbon fiber tubes are much lighter than traditional metal tubes, making them ideal for applications such as aircraft or spacecraft. The low weight of the material also makes it easier to transport and install.

Telescoping carbon fiber tubes are also easy to customize for specific applications. The flexibility of the material allows for easy adjustment of the tube’s length. This makes it ideal for applications such as telescoping antennas or robotic arms. The strength and flexibility of the material also make it ideal for applications that require a strong and durable tube.

Overall, telescoping carbon fiber tubes are a great option for applications that require strength, flexibility, and low weight. The material is strong and lightweight, which makes it ideal for applications in aerospace and automotive industries. The flexibility of the material allows for easy adjustment and customization, making it ideal for applications such as telescoping antennas or robotic arms. The low weight of the material also makes it easier to transport and install. With all of these advantages, it is clear why telescoping carbon fiber tubes are becoming more and more popular in the aerospace and automotive industries.

Carbon Fiber Telescoping Tube Assembly Instructions (Clamp Style)

Instructions on how to assemble carbon fiber telescoping tubes using DragonPlate carbon fiber tubes and clamp style connectors.

Composite Fiber Aramid Honeycomb Panels. With an aramid honeycomb core sandwiched between carbon fiber or fiberglass for rigidity, these panels are strong, but lightweight,. Twill Carbon Fiber Telescoping Tubes These twill carbon fiber telescoping tubes nest within one another and slide effortlessly. They are ideal for creating adjustable poles, robotics,. Uni Carbon Fiber Telescoping Tubes These Uni-directional carbon fiber telescoping tubes nest within one another and slide effortlessly. They are ideal for creating adjustable., Telescoping Carbon Fiber Tubes.