Telescoping Square Tube Aluminum

Okay, so picture this: I was helping my dad clear out his garage the other week. You know the drill. Stuff that’s been there since the dawn of time, dusty boxes, and things you swear you’ll use someday. In the back, buried under a pile of old tarps and a suspiciously sticky-looking lawnmower engine, I found it. A set of… well, they looked like fancy, skinny metal sticks. They were silver, smooth, and sort of… nested. You know, one inside the other. I fiddled with them for a bit, trying to pull them apart, and suddenly, WHOOSH! They extended. Like, magically. They went from being about three feet long to maybe six or seven. My dad just chuckled and said, “Oh yeah, those are the telescoping poles. We used them for the awning years ago.”

And that’s when it hit me. Telescoping square tube aluminum. It sounds incredibly technical, doesn’t it? Like something you’d find in a NASA manual or a high-end engineering textbook. But really, it’s just that simple, almost magical concept of things fitting inside each other, extending and retracting with ease. It’s that same principle that allows binoculars to bring distant mountains closer, or a camera lens to focus on a tiny ladybug. And in the world of materials, this seemingly unassuming design has some seriously cool applications. Forget rocket science for a second; let’s talk about something much more down-to-earth… or maybe up-in-the-air.

So, what exactly is telescoping square tube aluminum? Let’s break it down, no intimidating jargon allowed. We’re talking about aluminum tubes that are shaped like a square. Not round, like your average pipe, but distinctly square. And the "telescoping" part? That just means they're designed to slide within each other, just like those poles I found in my dad’s garage. Think of it as a set of nested boxes, but made of metal and built for strength and precision. Pretty neat, right?

Why square, though? That’s the question that popped into my head. Round tubes are pretty standard, aren’t they? Well, it turns out that square tubes have some distinct advantages, especially when you’re dealing with the whole telescoping act. For starters, they offer a more stable interlocking mechanism. Imagine trying to slide two round pipes together. There’s a lot of potential for wobble and misalignment, right? Square tubes, with their flat sides and corners, naturally resist rotation and provide a much more secure and precise fit. This is crucial when you need things to stay put and not jiggle around.

Think about it. If you’ve ever tried to extend a wobbly tent pole, you know the frustration. You’re trying to set up camp, and the whole thing feels like it’s going to collapse. Square telescoping tubes? They’re built to avoid that kind of amateur hour. They offer a smoother extension and retraction. The flat surfaces mean there’s less friction and less chance of getting them stuck. Plus, the corners provide natural guides, ensuring they slide in and out like a well-oiled… well, like well-oiled aluminum.

And let’s not forget the inherent strength of aluminum. It’s lightweight but incredibly strong. This makes telescoping square tube aluminum perfect for applications where you need both portability and durability. You don’t want something that’s going to buckle under pressure, but you also don’t want to lug around a ton of heavy metal. Aluminum hits that sweet spot beautifully. It’s resistant to corrosion, too, which means it can handle being out in the elements without falling apart. So, if you’re building something that’s going to live outdoors, this stuff is your new best friend. Trust me on this one.

So, Where Do We Actually See This Stuff?

This is where things get interesting. Once you know what to look for, you start spotting telescoping square tube aluminum everywhere. It’s not just in some obscure industrial setting; it’s woven into the fabric of our daily lives, often in ways we don’t even realize. It’s the unsung hero of a lot of everyday gadgets and structures.

The Great Outdoors and Beyond

Remember those awning poles I mentioned? That’s a classic example. Campers, RV owners, anyone who likes a bit of shade at a picnic – they’ve probably encountered telescoping poles. They allow you to set up a shelter quickly and easily, without needing a complex rigging system. And because they’re aluminum, they’re not adding a significant burden to your camping gear.

But it doesn’t stop there. Think about flagpoles. A really tall flagpole needs to be able to be assembled and disassembled, right? Telescoping sections make that incredibly practical. You can have a towering flagpole that, when collapsed, is manageable to transport and store. It’s the same principle as those awning poles, just on a grander scale.

And what about scaffolding? While you might see a lot of traditional scaffolding, there are increasingly modern systems that utilize telescoping elements for faster and more adaptable setup. This can be a real game-changer on construction sites, saving time and labor. Imagine a crew being able to adjust the height of their working platform on the fly without having to dismantle and reassemble entire sections. That’s efficiency, people!

Helping Hands (and Stuff)

What else? How about those adjustable work platforms or ladders that need to reach different heights? Yep, telescoping square tubes are often the backbone of those. They provide the adjustable length and the necessary stability to support someone working at an elevated position. Think about painters, electricians, or even window cleaners. They rely on this kind of adjustable, robust support.

Even something as seemingly simple as a lift system for a TV or a projector in a home theater setup might use telescoping aluminum. It allows you to hide your screen away when it’s not in use, and then smoothly extend it for movie night. Talk about a cool feature! It’s that blend of functionality and discreet design that makes it so versatile.

And consider display stands or exhibition booths. In the fast-paced world of trade shows and events, you need solutions that are quick to set up, easy to transport, and look professional. Telescoping elements in display structures allow for flexible configurations and rapid assembly, making the whole process less of a headache.

The Nitty-Gritty: Why It's So Good

Okay, so we’ve established what it is and where it is. But let’s dig a little deeper into why it’s such a popular choice for so many different applications. It's not just about looking cool (though it does look pretty sleek!). There are some serious engineering and practical advantages at play here.

Durability and Longevity

Aluminum, as a material, is already pretty darn good. It’s resistant to rust and corrosion, which is a massive plus, especially for anything that’s going to be exposed to the elements. Unlike steel, which can rust into oblivion, aluminum holds its own. When you combine that with the design of telescoping tubes, which often have robust interlocking mechanisms and protective coatings, you’re looking at a product that can last for years, even decades.

The square profile also contributes to its durability. The flat surfaces and defined corners distribute stress more evenly compared to a round tube, making it less prone to dents or deformation. So, even if it gets knocked around a bit (and let's be honest, things do get knocked around), it's more likely to survive the ordeal with its structural integrity intact.

Lightweight Champion

This is a big one. Seriously, if you’ve ever had to carry heavy equipment, you know the value of saving even a few pounds. Aluminum is significantly lighter than steel, making telescoping square tube aluminum ideal for anything that needs to be moved or assembled frequently. Think about the guys setting up event tents or constructing portable stages. They’re already dealing with a lot of gear. If that gear is made of lighter materials, it makes their job infinitely easier and safer.

This weight advantage also translates to lower shipping costs and reduced energy consumption for transportation. So, it’s not just good for the end-user; it’s good for the planet and the supply chain too. A win-win, wouldn't you say?

The Precision Factor

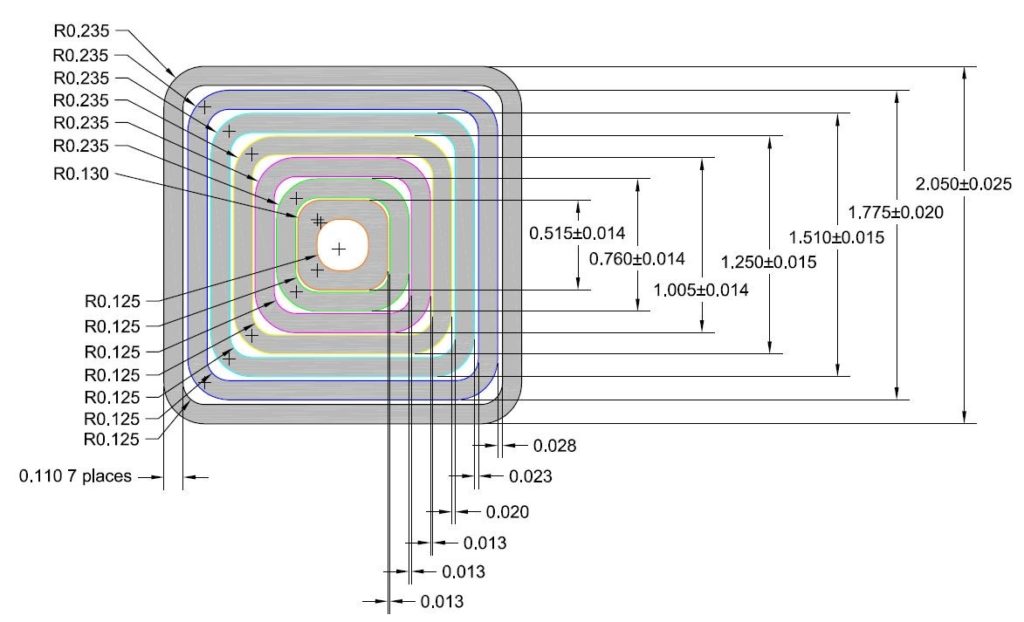

The precision with which telescoping square tubes can be manufactured is another key advantage. The tight tolerances required for smooth extension and secure locking mean that engineers can design systems with a high degree of predictability. You know that when you extend it, it’s going to extend to a specific length, and when you lock it, it’s going to stay locked.

This precision is essential for safety-critical applications, like scaffolding or adjustable ladders. You don’t want any guesswork involved when someone’s working at a height. The precise interlocking and locking mechanisms ensure that the structure remains stable and reliable under load. It’s that attention to detail that makes all the difference.

Versatility is Key

One of the most appealing aspects of telescoping square tube aluminum is its sheer versatility. Because it can be manufactured in various lengths, thicknesses, and with different surface finishes, it can be adapted to a huge range of applications. Whether you need a lightweight, portable solution or a robust, heavy-duty structure, there’s likely a telescoping square tube aluminum design that can meet your needs.

It can be cut, drilled, welded, and fabricated with relative ease, allowing for custom solutions to be developed quickly. This adaptability makes it a go-to material for designers and engineers looking for a flexible and reliable component in their projects. It’s like the Lego of the metal world, but way more grown-up and useful.

A Touch of Irony and Future Thoughts

It’s kind of funny, really. We’re talking about this incredibly practical, robust material that’s used in everything from construction sites to camping trips. Yet, the concept itself – things sliding inside other things – is so simple, so intuitive, it’s almost childlike. It’s like we’ve taken a basic idea and just made it stronger, more reliable, and more useful with the magic of aluminum and precision engineering. It reminds me of those nesting dolls you find in souvenir shops. You pull them apart, and there’s another one inside, and another one inside that. Except, you know, these can hold up a small building.

And the future? I can only imagine. As we become more focused on sustainable materials and efficient design, I suspect we’ll see even more innovative uses for telescoping square tube aluminum. Think about modular construction, where entire sections of buildings could be assembled and disassembled with ease. Or maybe even in more advanced robotics and automation, where adjustable, strong, and lightweight components are always in demand.

Perhaps we'll see it integrated into smart homes in ways we can't even conceive of yet, with furniture that reconfigures itself or structural elements that adapt to changing needs. The simple act of sliding one tube into another might just be the foundation for some seriously futuristic innovations. Who knew that finding a dusty set of poles in my dad’s garage would lead to such a fascinating exploration of material science and everyday ingenuity?

So, the next time you see something extendable and sturdy, take a moment to appreciate the clever design. It might just be the humble, yet remarkably capable, telescoping square tube aluminum at work. It’s a testament to how smart engineering can transform simple concepts into essential components of our modern world. Pretty cool, right? Now, if you’ll excuse me, I think I need to go find my dad’s awning poles again. I have a sudden urge to build a really impressive fort.