Telescoping Tube Binding Ratio. The multistage cylinder buckling using FEM was discussed earlier in literature [8][9][10][11][12] . Multistage cylinder buckling load using classical and. Structural Tubing Telescopic Connection. MVPs. iv63 (Structural) (OP) 6 Jan 09 23:13. Two pieces of tubular steel sections (round or square or rectangular) are.

Telescoping tube binding ratio is the ratio between the outer diameter of a tube and the inner diameter of another tube that fits within it. It is used to determine how much a larger tube can expand or compress in order to create a tight fit with an inner tube. This ratio is typically expressed as a decimal, such as 0.75, meaning that the inner tube is 75% of the size of the outer tube. This ratio is important for many different applications, such as designing a telescoping camera tripod, constructing a model rocket, or creating a collapsible shelter.

The most common way to calculate the telescoping tube binding ratio is to divide the outer diameter of the larger tube by the inner diameter of the smaller tube. For example, if the outer tube has an outside diameter of 4 inches and the inner tube has an inside diameter of 2 inches, then the telescoping tube binding ratio would be 0.5 (4/2). This means that the smaller tube is 50% of the size of the outer tube.

When choosing a tube binding ratio, it is important to consider the application in order to ensure a tight fit between the two tubes. For example, a larger ratio such as 0.75 may be suitable for a model rocket, where the tubes need to expand and contract in order to create a secure fit. On the other hand, a smaller ratio such as 0.5 may be better for a camera tripod, where the tubes need to remain securely in place during use.

The materials used in the tubes can also affect the telescoping tube binding ratio. For example, aluminum and steel tubes can usually achieve a tighter fit than plastic or PVC tubes. Additionally, the wall thickness of the tubes can also have an impact on the ratio. Thicker walls will create a tighter fit, while thinner walls will allow for more flexibility.

In addition to the materials used and the wall thickness, the telescoping tube binding ratio can also be affected by the surface finish of the tubes. A smooth, polished surface will create a tighter fit than a rough or unfinished surface. Additionally, the use of lubricants or coatings can also help to increase the binding ratio.

Finally, it is important to consider the environment in which the tubes will be used in order to determine the most suitable telescoping tube binding ratio. For example, a ratio of 0.75 may be sufficient for a model rocket, but a ratio of 0.5 may be necessary for a camera tripod that is used in outdoor conditions.

In summary, the telescoping tube binding ratio is the ratio between the outer diameter of a tube and the inner diameter of another tube that fits within it. This ratio is calculated by dividing the outer diameter of the larger tube by the inner diameter of the smaller tube. This ratio is important for many applications, such as designing a telescoping camera tripod or constructing a model rocket. The materials used, wall thickness, and surface finish of the tubes can all affect the ratio, and the environment in which the tubes are used should also be taken into consideration.

Homemade PIPE BENDER !

My INSTAGRAM : instagram.com/doctords18/… MAX TOOLS : kozul.hr/services/max-alati/ DASSY WORK CLOTHES : dassy.eu/en-gb/ EINHELL : einhell.hr/hr-hr.html Unior Tools : uniortools.com If I have helped you and if you liked this creative video sure to subscribe and like the video;) I'd much helped me …;) … Ako sam vam imalo pomogao i ako vam se svidio ovaj kreativni video obavezno se pretplatite i lajkujte video 😉 PUNO BIH…

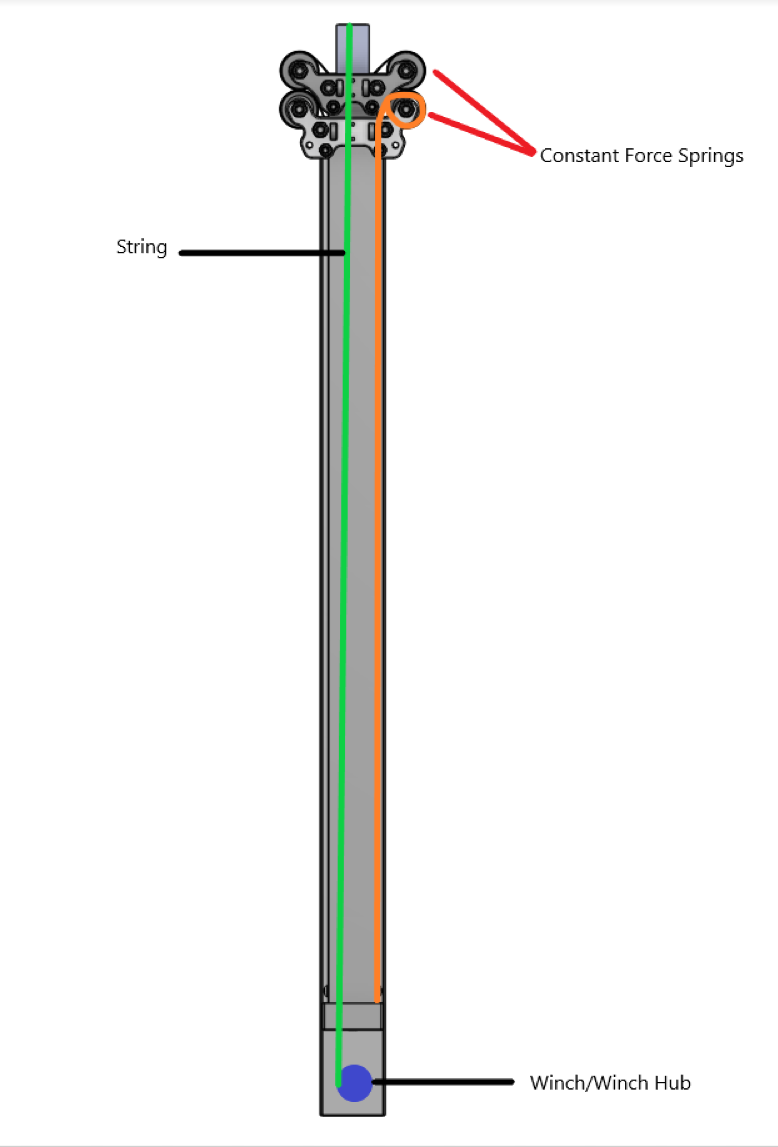

Telescopic tubes are perfect for applications requiring the different pieces of material to sleeve or expand inside one another. Our line of telescoping tubes is ideal for carts,. Each five-section telescoping tube assembly allowed for 16.2 m (637 in.) of vertical motion. The design of the LRU platform tubes was nearly identical to the OPF tubes. Operational. , Telescoping Tube Binding Ratio.