What Temp Does Steel Glow

Ever find yourself staring at a bonfire, mesmerized by the way the embers shimmer and the metal of a forgotten grill starts to… well, glow? It's a primal, almost magical sight, isn't it? That moment when something so solid and mundane transforms into a spectacle of light and heat. We’re talking about steel, that workhorse of industry and everyday objects, putting on a fiery show. But what's really going on there? And more importantly, what temperature does steel actually start to blush red?

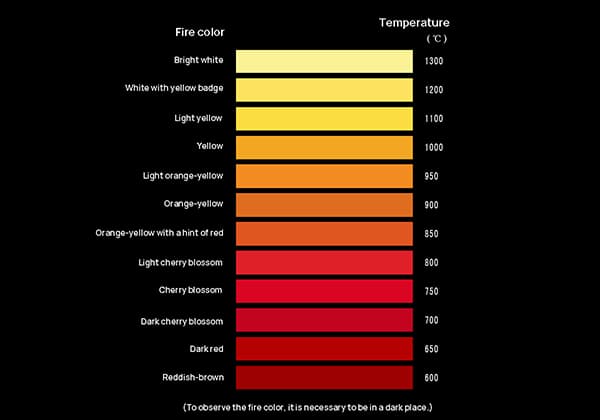

It's not a single, definitive number, you see. Think of it less like a light switch and more like a dimmer. Steel, like many metals, doesn't just flip from invisible heat to glowing red. It's a gradual, beautiful ascent. We're talking about a range, a spectrum of warmth that eventually leads to that fiery hue.

The First Whisper of Warmth: Cherry Red

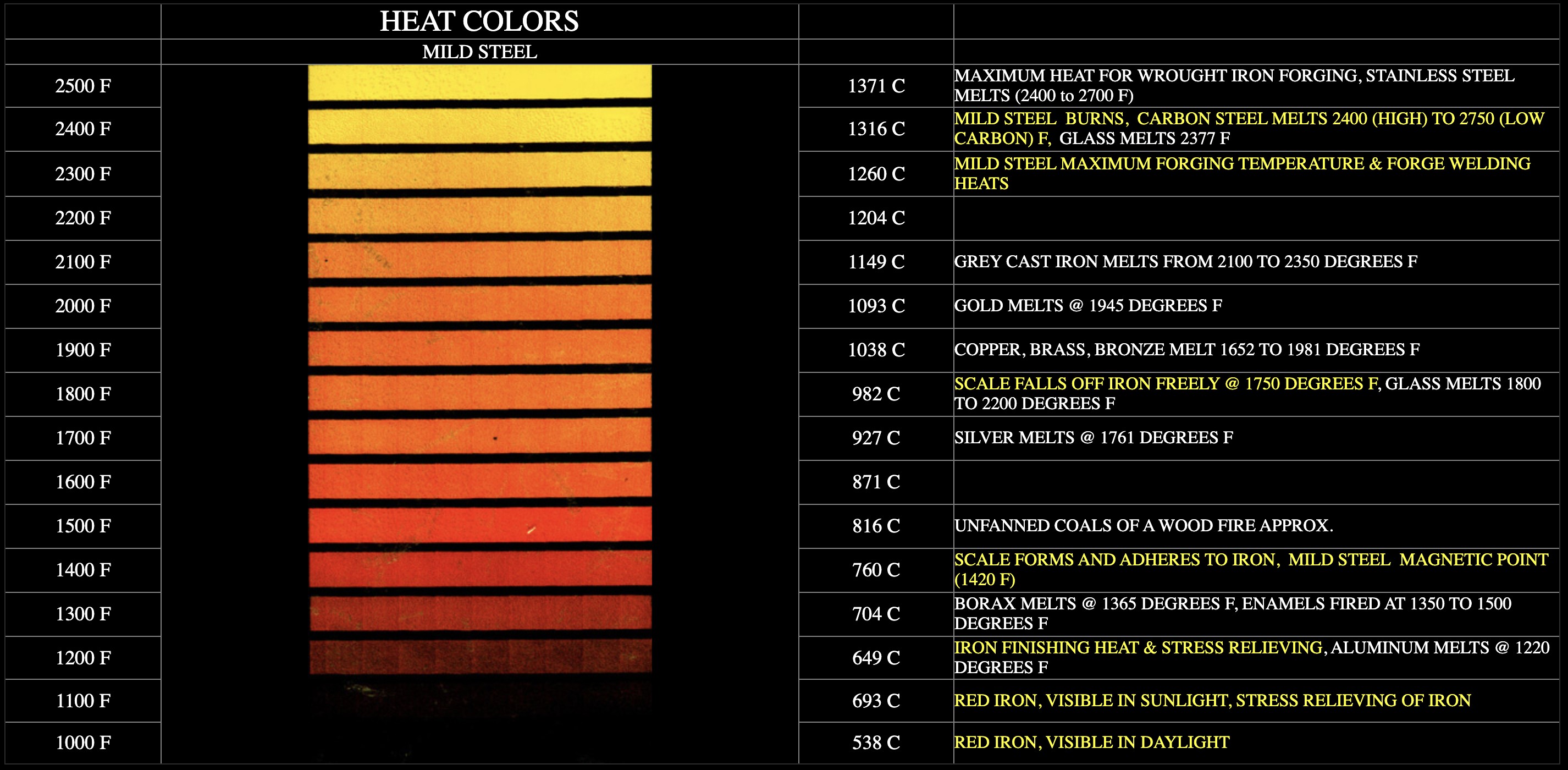

Before steel starts to truly glow in the way we imagine it – like something out of a medieval blacksmith's forge – it goes through some pretty impressive stages of warming up. The first real noticeable color change, the one that whispers "I'm getting toasty," happens around 900 to 1000 degrees Fahrenheit (482 to 538 degrees Celsius). This is often described as a "dull red" or a "cherry red" glow.

Imagine a really hot summer day, the kind where the asphalt shimmers. Steel at this temperature is definitely warmer than that, but it’s still relatively docile. It's the color of a smoldering ember, not an inferno. This is where many DIY projects and some industrial processes start to become interesting. Think of heat-treating tools or bending certain types of metal.

This temperature range is fascinating because it's just on the cusp. It's like the metal is taking a deep breath before it really commits to the heat. It’s warm enough to feel the energy radiating off it, to see that faint, almost shy blush. It’s not the dramatic glow you might see in a furnace, but it’s the beginning of the show.

And what’s happening at a molecular level? Well, as steel heats up, its atoms start to vibrate more and more vigorously. This increased energy causes them to emit electromagnetic radiation, including visible light. At these lower "glowing" temperatures, the emitted light is primarily in the longer, red wavelengths.

Picking Up the Pace: Bright Cherry and Orange

As we crank up the heat, the glow intensifies. From that initial dull red, steel progresses to a more vibrant "cherry red" and then into a distinct orange hue. This typically occurs between 1000 and 1400 degrees Fahrenheit (538 to 760 degrees Celsius).

This is the temperature range you’re often aiming for when you’re doing serious metalwork. Think of a blacksmith, shaping a horseshoe. That bright, almost fiery orange is the sweet spot. It's malleable enough to be worked with relative ease, yet hot enough to hold its shape once cooled.

It’s in this range that the visual impact really starts to hit home. The orange glow is unmistakable. It's vibrant, energetic, and frankly, pretty darn cool to watch. This is the color of a well-managed campfire at its peak, or the internal glow of a kiln firing pottery.

Culturally, this color has always been associated with power and transformation. Think of the phoenix rising from the ashes, or the mythical forges of Hephaestus. The orange glow of heated metal embodies creation and resilience. It’s the color of a new beginning forged in intense heat.

And a fun little fact? Different alloys of steel will glow at slightly different temperatures. The carbon content and other elements can subtly alter how quickly and intensely the metal changes color. So, not all oranges are created equal when it comes to steel!

The Inferno: Yellow and White Hot

Now we’re talking about serious heat. As the temperature climbs beyond 1400 degrees Fahrenheit (760 degrees Celsius), steel transitions into a brilliant yellow and then into a blinding white hot glow. This can go all the way up to 2500 degrees Fahrenheit (1370 degrees Celsius) and beyond, depending on the specific steel alloy and application.

This is the realm of industrial furnaces, the heart of steel mills, and the extreme conditions needed for certain welding processes. At these temperatures, steel is practically liquid, ready to be poured and shaped into the infrastructure that supports our modern lives.

Watching steel at these temperatures is an almost awe-inspiring experience. It’s pure, unadulterated energy made visible. The white hot glow is so intense it can be painful to look at directly, a testament to the sheer power being unleashed.

Think of the iconic imagery from movies: the molten steel pouring from a furnace, a cascade of liquid fire. That's the yellow to white hot stage. It’s raw, primal, and incredibly beautiful in its ferocity. It's the color of the sun's surface, a reminder of the immense energy that can be contained and harnessed.

In industries that work with steel at these temperatures, safety is paramount. We’re talking about specialized equipment, protective gear, and highly trained professionals. It's a world where precision and respect for the immense forces at play are non-negotiable.

And here's another cool bit: when steel is white hot, it’s emitting radiation across a much broader spectrum, including a significant amount of ultraviolet light. This is why those extreme glows can be so dangerous for unprotected eyes.

Practical Tips for the Curious (and Cautious!)

So, you might be thinking, "This is fascinating! Can I try this at home?" Well, with a big caveat: safety first, always. Working with high temperatures is inherently dangerous.

If you're dabbling in anything that involves heating metal, even for something as simple as bending rebar for a garden trellis, understand the basics. Start with the lowest effective temperature. If you're using a torch, practice on scrap pieces to get a feel for the color changes.

For hobbyists, a propane torch might get you to that dull red stage, but anything hotter usually requires specialized equipment like a forge. If you're interested in blacksmithing or metalworking, seek out experienced mentors and classes. They can teach you the proper techniques and, more importantly, the crucial safety protocols.

Never work alone when dealing with significant heat sources. Have a fire extinguisher or a bucket of water (depending on the material you're working with) readily available. Wear appropriate protective gear, including heat-resistant gloves and eye protection. And remember, even a seemingly "cool" piece of metal can retain significant heat for a long time.

Think of it like cooking. You don't jump straight to searing a steak at 600 degrees without understanding the process. Heating metal has its own culinary arts, and they require a healthy dose of respect for the heat.

Cultural Echoes: From Mythology to Modern Marvels

The glowing of steel is more than just a scientific phenomenon; it's woven into the fabric of human culture and storytelling. From ancient myths to modern engineering, the transformative power of heat and metal has always captivated us.

In Greek mythology, Hephaestus, the god of blacksmiths, was said to have his forge in the heart of Mount Etna, where he crafted divine weapons and armor. The fiery glow of his work was a symbol of creation, power, and divine craftsmanship.

Later, during the Industrial Revolution, the sight of glowing furnaces and molten metal became synonymous with progress and innovation. These images represented humanity's growing mastery over natural forces, shaping the world with steel and fire.

Even in our everyday lives, we see the influence. The warm, inviting glow of a hearth fire, reminiscent of that initial dull red of heated metal, evokes feelings of comfort and home. And the sleek, strong structures built from steel, from skyscrapers to bridges, are a testament to the material's incredible properties, properties unlocked by heat.

It's this duality – the fierce power of the forge and the humble strength of the finished product – that makes the glowing of steel so compelling. It’s a reminder that even the most solid materials have a fluid, transformative potential when subjected to the right conditions.

A Daily Reflection: The Heat Within

Thinking about steel glowing might seem far removed from our daily routines. But there's a subtle connection, a gentle echo of that intense transformation in our own lives. We all experience moments of "heat" – periods of intense effort, passion, or even stress.

Sometimes, these moments feel like we're being forged. We're pushed to our limits, our resilience is tested, and we undergo a kind of internal transformation. Just as steel needs intense heat to be shaped into something strong and useful, we often need challenging experiences to grow and become more resilient.

And just like the gradual glow of steel, our own growth isn't always a sudden, dramatic event. It's often a series of small, incremental changes, a slow warming up to new possibilities, a gradual transformation that, over time, makes us stronger, more adaptable, and capable of enduring life's fiercest fires.

So, the next time you see a hint of red in a heated piece of metal, or even feel a surge of passionate energy within yourself, remember the journey. Remember the science, the history, and the quiet power of transformation that lies within even the most ordinary of materials – and ourselves.