Telescoping load bearing tube is a versatile tool that is used in a variety of applications. It is commonly used in construction projects, as it can be used to support heavy loads without compromising the structural integrity of the material. Telescoping load bearing tube is also used in the automotive industry for exhaust systems, suspension systems, and other components.

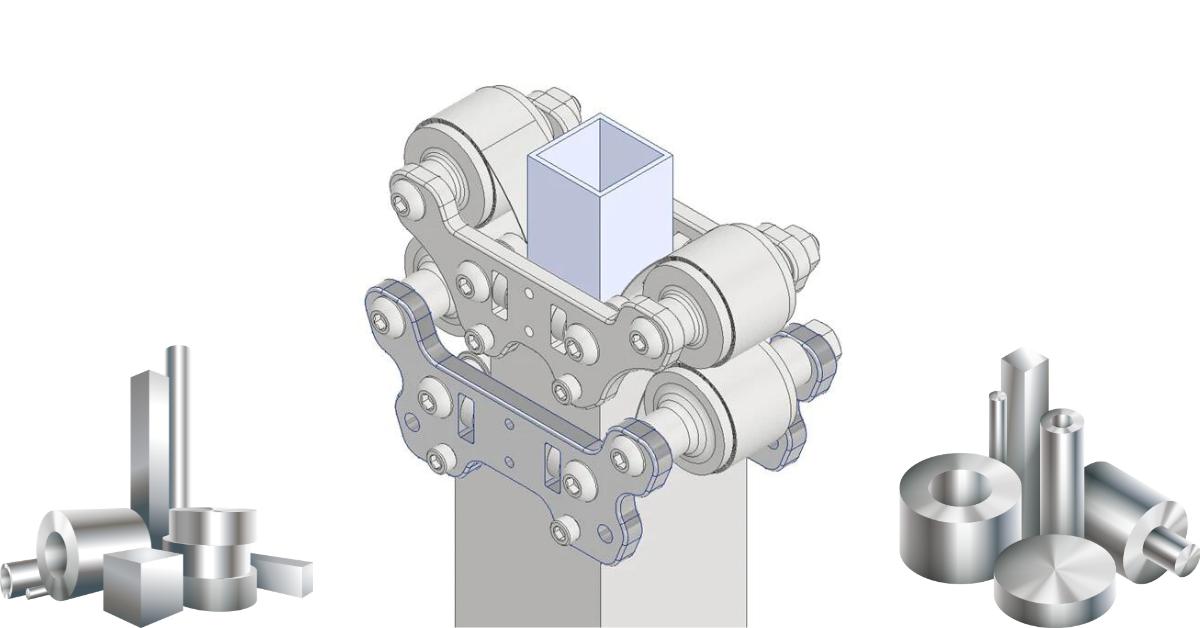

Using telescoping load bearing tube is fairly straightforward. It is composed of a tube with a series of smaller tubes that fit inside of one another. The smallest tube is the load bearing tube, while the larger tubes provide the structural support. Depending on the size and weight of the load, different sizes of telescoping load bearing tubes can be used.

To install the telescoping load bearing tube, the first step is to secure the main tube in the desired location. It is important to make sure that the tube is properly secured in order to ensure that the load is evenly distributed and that the tube does not move during use. Once the tube is secured, the smaller tubes can be inserted into the main tube.

Next, the smaller tubes must be properly secured. This is usually done by using screws or bolts. It is important to use the correct size of screws or bolts in order to ensure that the load is evenly distributed. If the screws or bolts are too loose, the load bearing tube may move or shift during use, which can cause damage to the structure or the load.

The final step is to connect the load bearing tube to the structure. This can be done by welding or bolting, depending on the application. It is important to make sure that the connection is secure and that the load is evenly distributed. Once the connection is secure, the telescoping load bearing tube is ready for use.

Telescoping load bearing tube is a versatile and reliable tool for a variety of applications. It is important to make sure that the tube is properly secured and that the load is evenly distributed in order to ensure the safety of the structure and the load. With proper installation and use, telescoping load bearing tube can be a valuable tool for any project.