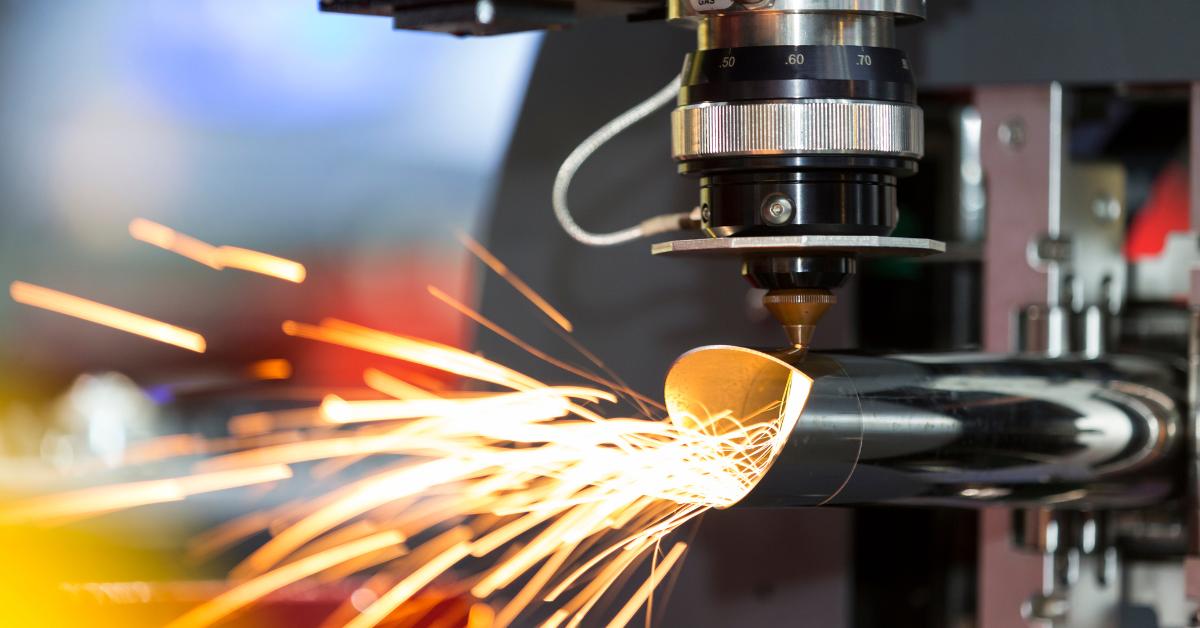

Lasers are optical sources that emit charged photons in the form of a beam. Laser technology was first developed in the 1960s, and scientists proposed that it was a variation of the Maser Principle. Laser technology has seen rapid advancements since its first development. Currently, technology can be found in many disciplines, such as medicine, consumer electronics, science, and industrial applications. This article is about the use of lasers in laser welding systems.

One industrial application that has taken advantage of the laser technology is welding. Laser welding systems are used to repair miniature components, automotive, aerospace instrumentation, and sensor technology. The electronics and electrical industries also use this technology in the manufacturing of devices. Laser welders are used for hermetically sealing and encapsulating electrical components such as switches.

Laser welding systems are used for the manufacturing of tube assemblies and hypodermic needles. The tungsten filaments that are a part of halogen bulbs are laser welded. (CNC) Computer numeric controls can be used in conjunction with laser welding equipment. This technology allows laser welders to perform some of the most difficult welding, one of which is thin-walled tubing. A laser welding beam can be focused to .0005mm in width. This allows a machining operator to use computer controls to weld intricate and complex jobs. The fiber optic beam delivery systems, as well as conventional systems, are used to deliver laser welds.

Laser welding machines are quickly becoming the preferred machines that welders use as opposed to beam welding equipment, which is much more costly. A beam welding machine can cost anywhere from $8,000 to $15,000 dollars when compared to a laser welding machine, whose cost may vary from $2,000 to $3,000 dollars. The laser welding process is much faster and more efficient; however, there is one drawback to laser welding technology. Lasers have a maximum thickness penetration of 1/8 of an inch, which is too weak for many industrial applications.

Research is currently focused on developing advanced laser welding systems that can be used to produce the microscopic devices needed for the medical field. This technology holds the promise of boosting the diseased fighting capabilities of modern medicine.

When it comes to laser welding, the advantages of using a fiber laser far outweigh those of using the conventional YAG laser when laser plastic welding and metals. Here are some advantages of fiber lasers:

- More functionality: Fiber lasers support a wider range of welding techniques and operations for plastics and metals. They can be used to weld intricate designs and produce more specialized welding effects.

- Economical: Fiber lasers work on demand so there is no need for a warm-up process this reduces the consumption of energy, plus they are roughly 10 times more efficient when compared to the traditional Nd:YAG lasers.

- Faster throughput: They can operate in a non-stop CW mode or continuous wave and in a pulse mode of 100 kHz.

- Reduced down or align time: Fiber lasers do not carry lamps that need changing, and they do not have mirrors that need cleaning. They are basically low-maintenance equipment.

- Robot mounting options: The high-quality beam allows welders to use it over longer distances. These machines can also be mounted using robots. This will allow welding to take place in areas that are inaccessible to humans.

- High process yield: Once a fiber laser is turned on, it provides a stable power output from the beginning of the process until the end. If it is being used in pulsed mode, each pulse carries an identical output from the start to the end of the process. In a continuous wave mode, the output is stable over time.

As you can see, the fiber lasers are great candidates for your laser welding systems.