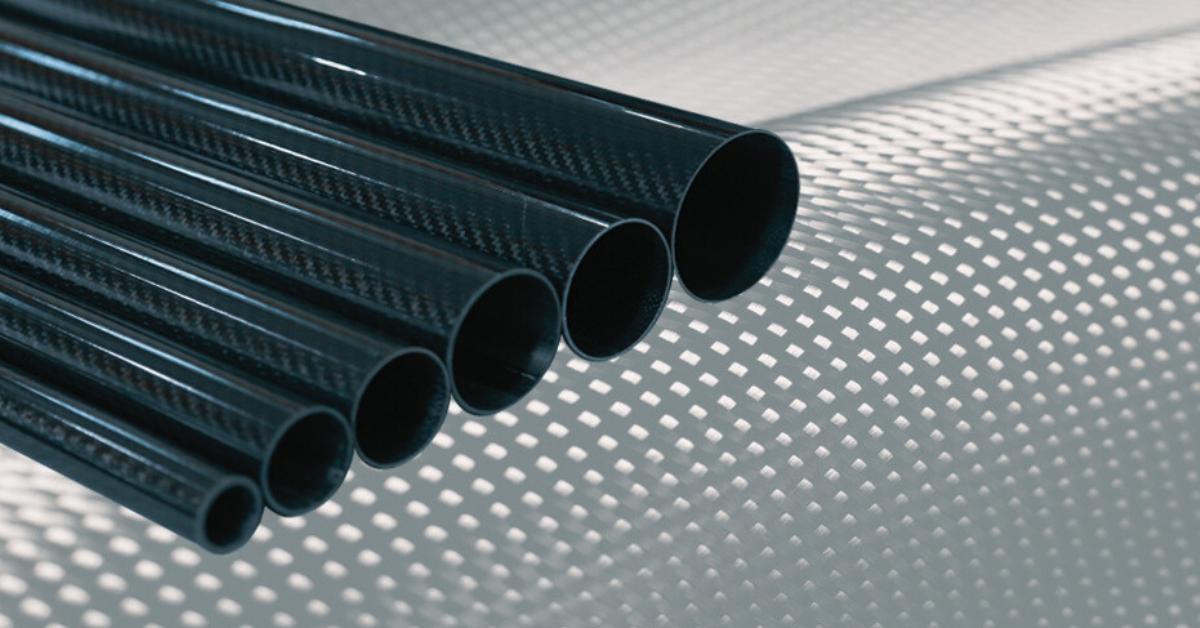

More and more often these days, carbon fiber telescopic tube replace steel, titanium, or aluminum telescopic tubes in applications where weight is an important factor. Weighing in at as little as ⅓ the weight of aluminum tubes, it’s no wonder that carbon fiber telescopic tubes are often the preference in industries such as aerospace, high-performance vehicles, and sporting equipment, where weight is a crucial factor.

Carbon fiber telescopic tubes are composite tubes made out of carbon fiber. They are often used in applications where strength, stiffness and lightweight are of utmost importance. Carbon fiber telescopic tubes have a wide range of applications, from aerospace to medical.

Also Read

Carbon Fiber Telescopic Tube Properties

One of the main characteristics of carbon fiber telescopic tubes is their strength and stiffness. The combination of carbon fiber and resin creates a material that is extremely strong and light, making it an ideal choice for many applications. Carbon fiber telescopic tubes are also resistant to corrosion and can be used in a variety of environments. The tubes are strong enough to support a large amount of weight, yet light enough to be easily transported.

Some of the unique properties that make carbon fiber telescopic tubes preferable to tubes made of other materials include:

- High strength-to-weight and stiffness-to-weight ratios

- Resistance to fatigue

- Dimensional stability due to an extremely low coefficient of thermal expansion (CTE)

Another characteristic of carbon fiber telescopic tubes is their flexibility. The tubes can be bent and shaped into a variety of shapes, allowing for a wide range of uses. Carbon fiber telescopic tubes are also resistant to vibration and shock, making them ideal for applications that require stability and durability.

Carbon Fiber Telescopic Tube Characteristics

Carbon fiber telescopic tubes are typically produced in circular, square, or rectangular shapes, but they can be fabricated into almost any shape, including oval or elliptical, octagonal, hexagonal, or custom shapes. Roll-wrapped prepreg carbon fiber tubes consists of multiple wraps of twill and/or unidirectional carbon fiber fabric. Roll-wrapped tubes work well for applications that need high bending stiffness combined with low weight.

Alternatively, braided carbon fiber telescopic tubes are made up of a combination of carbon fiber braid and unidirectional carbon fiber fabric. Braided tubes offer excellent torsional characteristics and crush strength, and they are well-suited for high-torque applications.

Large diameter carbon fiber tubes are typically constructed using rolled bi-directional woven carbon fiber. By combining the right fiber, fiber orientation, and fabrication process, carbon fiber tubes can be created with the proper characteristics for any application.

Other characteristics that can be varied by application include:

- Materials : Telescopic Tubes can be fabricated from standard, intermediate, high, or ultra-high modulus carbon fiber.

- Diameter : Carbon fiber tubes can be made from very small to large diameters. Custom ID and OD specifications can be met for particular needs. They can be made in fractional and metric sizes.

- Tapering : Carbon fiber tubes can be tapered for progressive stiffness along the length.

- Wall thickness : Prepreg carbon fiber tubes can be fabricated to virtually any wall thickness by combining layers of various prepreg thicknesses.

- Length : Roll-wrapped carbon fiber tubes come in several standard lengths or can be built to a custom length. If a requested tube length is longer than recommended, multiple tubes can be joined with internal splices to create a longer tube.

- Exterior and sometimes interior finish : Prepreg carbon fiber tubes typically have a cello-wrapped gloss finish, but a smooth, sanded finish is available, too. Braided carbon fiber tubes typically come with a wet-looking, shiny finish. They can also be cello-wrapped for a glossier finish, or a peel-ply texture can be added for better bonding. Large diameter carbon fiber telescopic tubes are textured on both the interior and exterior to allow for bonding or painting of both surfaces.

- Exterior materials : Using prepreg carbon fiber tubes allows for the option of selecting different exterior layers. In some cases, this can also allow the customer to select the exterior color.

The Applications and Uses

Carbon fiber telescopic tubes are used in a variety of industries. They are used in aerospace for the construction of airframes and other components. They are also used in the medical industry for the construction of medical devices and prosthetics. They are used in the automotive industry for the construction of body panels, suspension components, and more.

Some current common applications and uses include:

- Robotics and automation

- Telescoping poles

- Metrology instrumentation

- Idler rollers

- Drone components

- Telescopes

- Lightweight drums

- Industrial machinery

- Guitar necks

- Aerospace applications

- Formula 1 race car components

In order to construct a carbon fiber telescopic tube, the following steps are required:

- Gather the necessary materials, including carbon fiber and resin

- Prepare the carbon fiber by cutting it into the desired shape

- Prepare the resin by mixing it with a catalyst

- Lay the carbon fiber in the desired shape and apply the resin

- Pressure cure the carbon fiber and resin to complete the tube

With their light weight and superior strength and stiffness, combined with a wide array of customizable options, from fabrication process to shape to length, diameter, and sometimes even color options, carbon fiber telescopic tubes are useful for numerous applications across many industries. The uses for carbon fiber telescopic tubes are really only limited by one’s imagination!