With the presence of telescopic tube on the market, you can easily find and buying telescopic tube for your needs. However, this doesn’t always mean that people are familiar with telescopic tube.

If you’re a metallurgical engineer, you’re likely familiar with telescopic tubes. Telescopic tubes are cylindrical structures that are designed to fit inside one another. The purpose of telescopic tubes is to save space, providing a collapsible structure for various applications. Telescopic tubes are commonly used in such applications as automotive suspension, furniture construction, and any other application that requires a collapsible structure.

Also Read

Does this sound like something new to hear? If you simply answer yes, then it would be better to get to know more about it, its uses, and the choices of telescpoic tube types available. Before you go to buy it, it’s important to ask yourself whether you have a clear reason for making the purchase. However, any item or product you buy must provide you with the potential or great return on investment.

The Uses of Telescopic Tube

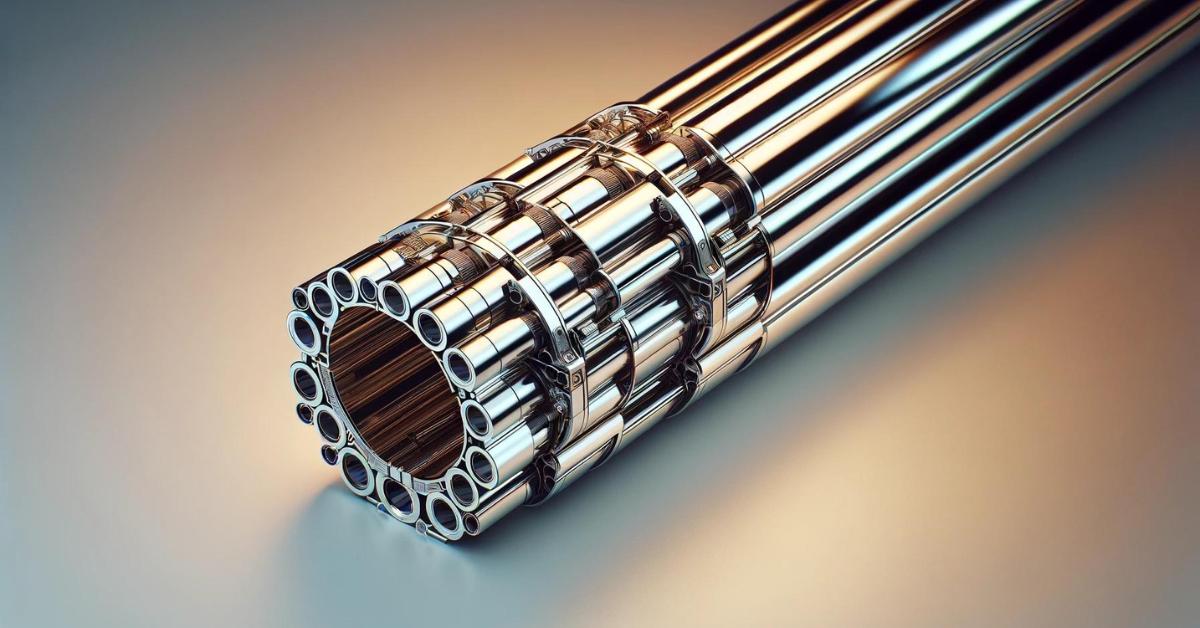

The design of telescopic tubes is relatively simple. They are composed of a series of tubes that are nested within each other. Each tube has a slightly smaller diameter than the one outside of it. This allows them to fit snugly within each other, while still providing a strong, stable structure. The tubes are also designed with a lip, which helps keep the tubes locked into each other.

To construct a telescopic tube, you’ll need a series of tubes of varying diameters. The tubes should be made from a strong and durable material, such as steel or aluminum. Once you have your tubes, you’ll need to cut them to the desired length, and then attach the lip to each tube. The lip should be securely attached to the tube, ensuring that it won’t come off during use. Finally, the tubes should be placed one inside the other, with the lip facing outward.

Telescopic tubes are perfect for applications requiring the different pieces of material to sleeve or expand inside one another. Telescoping is required when the ability to adjust tubing or piping to one object for an unknown or constantly-changing width is essential. Examples include adjustable table legs, shower curtains, railing, metal supports, and telescopic camera tripods.

Telescopic Tube Applications

The use of upside-down suspension is now widely applied by many brands of motorcycles, even to small cc capacity motors. In appearance, the suspension upside down is more interesting when compared to telescopic suspension.

Then, what distinguishes these two types of suspension? An easy to see a difference between these two suspensions is the position of the inner tube (small tube) and an outer tube (large tube).

On the type of upside down, the position of the inner tube is at the bottom and the outer tube is above. While the telescopic tube type at the top is the position of the inner tube and outer tube below.

The striking difference is only in the placement of the tube. Upside down the tube is above and the small one below. Once the opponent is telescopic.

The next difference is based on how the suspension works. The type of upside down is intended so that the upper hand part is bigger. This is to reduce the vibrations produced when the motor is being driven so that better damping. This type of upside down telescopic tube is created so that the upper handle is bigger so that it can be better damping.

Types of Telescopic Tube

Telescopic Tube Shapes

- Round Telescopic Tube

- Rectangular Telescopic Tubing

- Square Telescopic Tube

Telescopic Tube Materials

- Aluminum Steel Tube

- Stainless Steel Tube

- Hot Rolled Steel Tubing

- Cold Rolled Steel Tubing

- .. and any other steels/metals

Maintenance

Telescopic tubes require regular maintenance in order to keep them in good working order. This includes inspecting the tubes for any signs of damage, such as cracks or rust. If any damage is found, it should be repaired as soon as possible. Additionally, the tubes should be lubricated regularly in order to reduce friction and extend their life. Finally, the tubes should be inspected for any signs of wear or fatigue, as this could lead to failure.

When using telescopic tubes, it’s important to ensure that they are properly secured. This means that the lips should be firmly attached to the tubes, and that the tubes should be locked into each other. If the tubes are not properly secured, they could become loose, which could lead to malfunctioning or even collapse. It’s also important to make sure that the tubes are properly lubricated, as this will help to reduce friction and extend the life of the telescopic tube.

Telescopic tubes are a great way to save space in a variety of applications. They are relatively easy to construct, and require minimal maintenance. However, it’s important to make sure that they are properly secured and lubricated, as this will help to ensure that they remain functional and safe. If you’re a metallurgical engineer, being familiar with telescopic tubes is an important part of your job.

Finally after reading the above article, we hope that you being familiar with telescopic tube and can identify for the top quality steel tube your application requires.