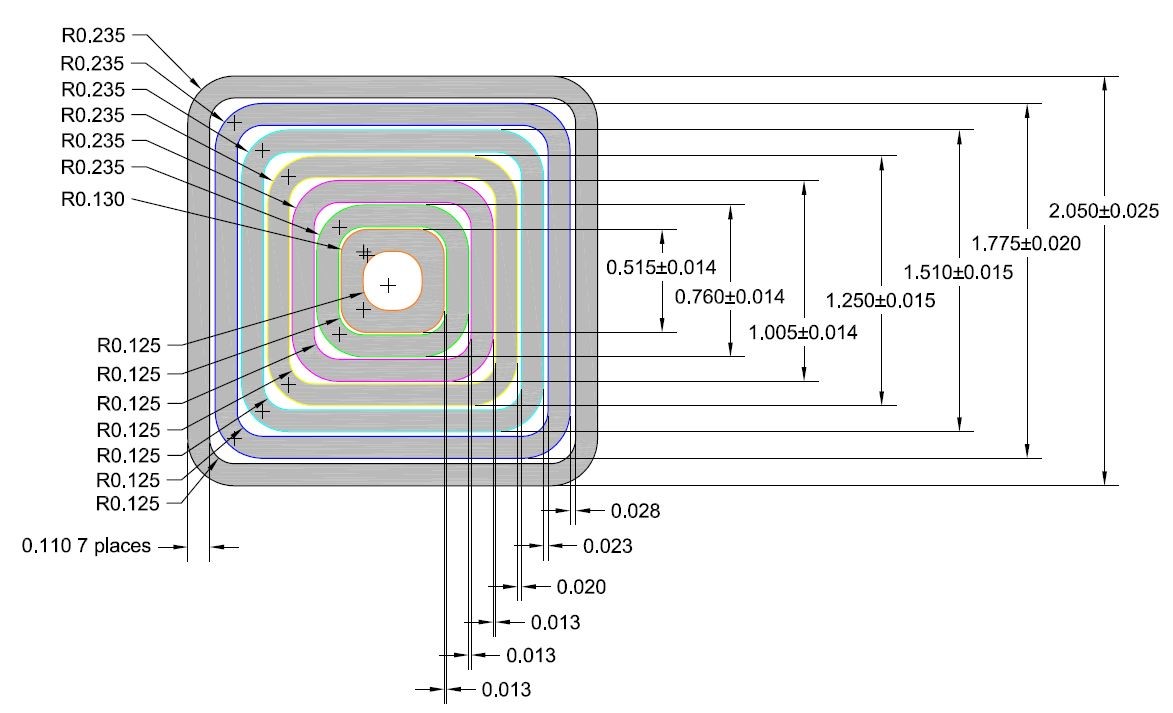

Telescoping Dimension Steel Square Tubing. Square Tubing is the most commonly used shape when telescoping (.100″ or 14GA with .083″ wall). Tips for Round Steel Tubing To obtain the approximate inside. Telescoping Corrosion-Resistant 3003 Aluminum Tubes These tubes are sized so that each tube fits into the next larger size. Ultra-Formable 260 Brass Round Tubes The most.

Telescoping dimension steel square tubing is a type of steel tubing that is used for a variety of different projects. The tubing is formed in a square shape and is designed to be able to fit together at multiple points along its length. This allows for the tubing to be easily adjusted to fit any size or shape of structure that it is used for. Telescoping dimension steel square tubing is available in a variety of sizes, ranging from small to large.

Also Read

The most common method of constructing telescoping dimension steel square tubing is by welding them together. This is done by welding the two pieces at the corners and then closing the gap between them. This is often done with a welding machine, although it is also possible to hand weld if the necessary equipment is available. It is important to ensure that the welds are made correctly and that there are no gaps in the welds.

Once the telescoping dimension steel square tubing has been welded, it is then ready to be cut to the desired length. This can be done with a saw, jigsaw, or other cutting tool. It is important to follow the manufacturer’s instructions when cutting the tubing, as this will help to ensure that the tubing is properly cut and will not be damaged during the cutting process.

When cutting telescoping dimension steel square tubing, it is important to note that the tubing will have an internal and external diameter. This means that the tubing should be cut to the appropriate size for the internal and external diameters. This will help to ensure that the tubing is cut properly and will not be too small or too large for the project.

Once the telescoping dimension steel square tubing has been cut to the desired size, it is then ready to be installed. This can be done by drilling holes in the tubing and then inserting bolts or rivets into the holes. This is a fairly simple process and can be done with basic tools, such as a drill, screwdriver, and rivets.

It is also possible to purchase telescoping dimension steel square tubing that is already pre-cut to the desired size. This can be a great time saver, as it eliminates the need for cutting and drilling. However, it is important to note that pre-cut tubing may not fit the exact size and shape of your project, so it is best to measure and make sure that the pre-cut tubing will fit before ordering it.

Telescoping dimension steel square tubing is a great material for many different projects. It is easy to cut, weld, and install, and it can be purchased in a variety of sizes. When using telescoping dimension steel square tubing, it is important to measure, cut, and install the tubing correctly to ensure that the project is completed successfully.

Tips For Telescoping Tube | Metal Supermarkets

In this video blog, we review our top tips for telescoping tube. If you need tube for your next project, visit: metalsupermarkets.com/

12L14 Steel Cold Finished Round Bar. A 36 Hot Rolled Steel. 1045 Turned-Ground-Polished Steel Shafting. Carpenter 158. 3/4" Diameter Carpenter 158 Round Bar.. Square Tubing Continued on next page Mechanical Tubing: Under 2" or 11 ga and under – ASTM A-513. Structural Tubing: 2" and over 11 ga wall thickness – ASTM A-500. , Telescoping Dimension Steel Square Tubing.