Telescoping Carbon Fiber Tube. We carry the highest quality carbon fiber tubes and carbon fiber tube collets made in the USA. Connect with us to learn more about custom orders and volume discounts.. 1.1K subscribers. Instructions on how to assemble carbon fiber telescoping tubes using DragonPlate carbon fiber tubes and connectors. Both collet and clamp style. Uni Carbon Fiber Telescoping Tubes. These Uni-directional carbon fiber telescoping tubes nest within one another and slide effortlessly. They are ideal for creating adjustable.

Telescopic carbon fiber tubes are becoming increasingly popular for a wide range of applications due to their superior strength and lightweight design. Carbon fiber is a composite material made from strands of carbon fibers woven together and bonded with epoxy resin. The result is a material that is strong yet lightweight, making it ideal for a variety of applications. Telescopic carbon fiber tubes can be used in a variety of ways, from simple structural components to complex assemblies.

Also Read

Manufacturing Process

The manufacturing process for telescopic carbon fiber tubes involves several steps. First, the raw carbon fiber strands are woven together and then impregnated with epoxy resin in a rolling process. The impregnated strands are then cut to the desired length and placed in a mold. The mold is heated and pressure is applied to form the tube. After the tube is formed, it is inspected for defects and then coated with a protective finish to protect it from the elements.

Once the tube is formed, it is cut to length and then the ends are machined to create a telescoping joint. The joint is created by cutting a groove into the end of the tube and then bonding two male and female parts together. The joint is then sealed with an epoxy to prevent it from coming apart. The finished telescoping joint allows the tube to extend and retract, making it ideal for applications such as flag poles and antenna masts.

Telescopic carbon fiber tubes are incredibly durable and can withstand a wide range of temperatures and environments. They are also highly resistant to corrosion, making them ideal for applications that may come in contact with salt water or other corrosive substances. In addition, they are lightweight yet strong, making them well suited for applications that require a lightweight yet strong structure.

Telescopic carbon fiber tubes are becoming increasingly popular due to their superior strength and lightweight design. They are ideal for a variety of applications, from simple structural components to complex assemblies. With their excellent strength and corrosion resistance, telescopic carbon fiber tubes are an ideal choice for many applications.

Telescoping Carbon Fiber Tube Assembly Instructions

Instructions on how to assemble carbon fiber telescoping tubes using DragonPlate carbon fiber tubes and connectors. Both collet and clamp style connectors are shown in this video. For more information on how to create your own carbon fiber telescoping tubes go to dragonplate.com/carbon-fiber-telescoping-tubes

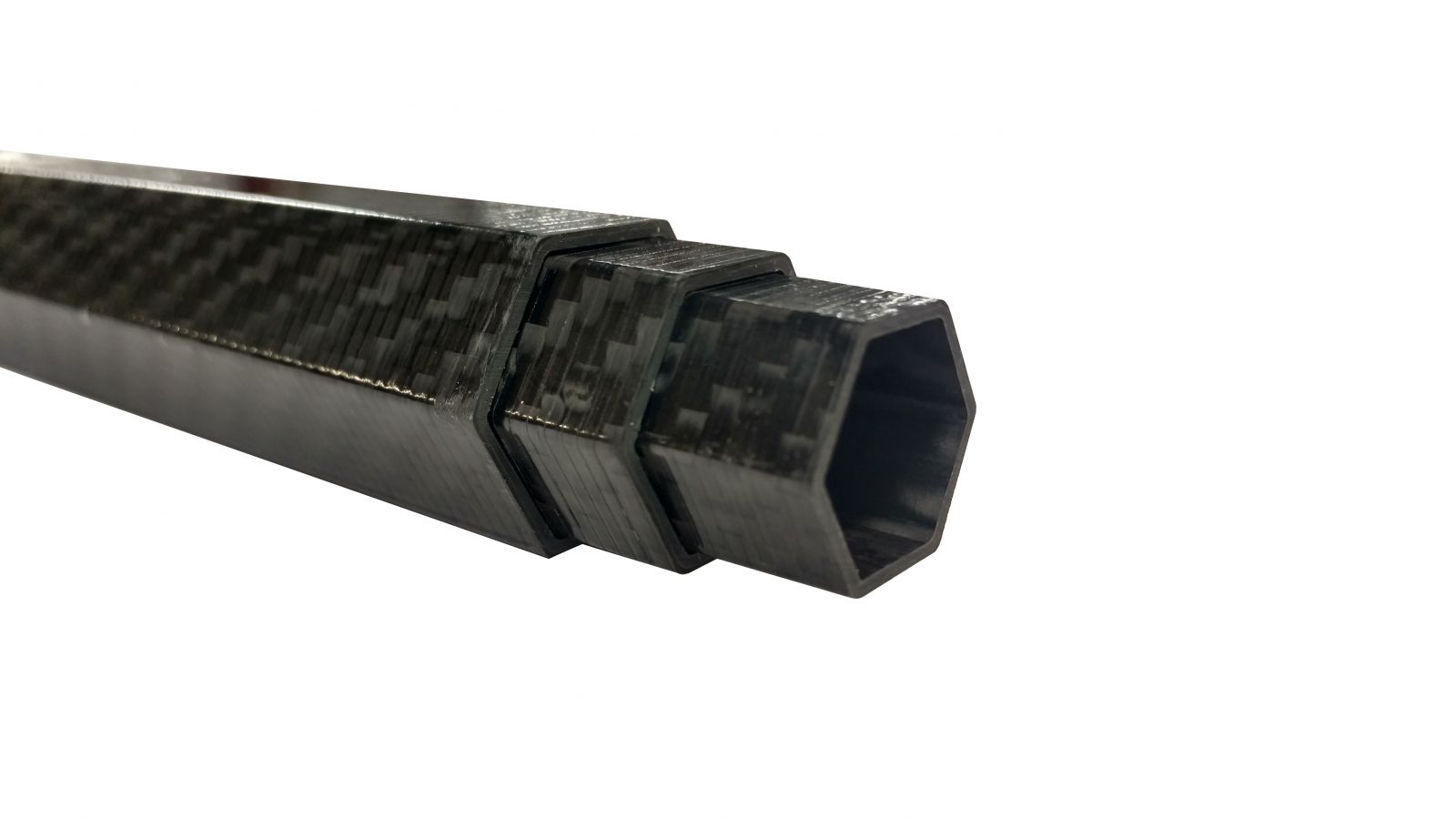

Carbon Fiber Hexagonal Tubes Fit these lightweight tubes inside each other to create adjustable tubes for structural framing, machinery components, and robotics. Pins for. Carbon Fiber Deflection Optimized Telescoping Tubes Dragonplate deflection optimized telescoping tubes are engineered using Nastran FEA composite modeling. Unlike the. Telescoping carbon fiber tubes, carbon fiber tube connectors / clamps designer and global marketing. Lanbao Sci&Tech Development Limited. 2014 年 2 月 – 至今9 年 3 个月.., Telescoping Carbon Fiber Tube.