Telescoping Square Tubing Sheet Metal. Telescoping tube is highly versatile and can be used for telescoping or splicing applications, or as an add-on component. Read more about galvanized square. Telescopic Tubing. Telescopic tubes are perfect for applications requiring the different pieces of material to sleeve or expand inside one another. Our line of telescoping tubes. Square Steel Tubes: Withstands extreme temperatures, pressures, and elements, making it perfect for commercial and industrial applications. It is used frequently in truck beds,.

Telescoping square tubing sheet metal is a modern fabrication process that allows for the efficient creation of finished products with minimal waste. It utilizes a combination of CNC laser cutting and precision-welding techniques to create a product of superior quality and strength. This method offers many advantages over traditional methods of fabrication, such as increased accuracy, reduced production time, and improved safety. Additionally, telescoping square tubing sheet metal has a wide range of applications in industries such as automotive, aerospace, and medical.

Also Read

What is Telescoping Square Tubing Sheet Metal?

Telescoping square tubing sheet metal is a manufacturing process that involves the use of CNC laser cutting to create a precise, high-strength product. The process begins with a computer-generated design that is then cut into a sheet of metal. This sheet is then fed into a CNC laser machine, where it is cut into the required shape and size. Once the parts have been cut, they are welded together using precision-welding techniques to create a more durable product.

The process of telescoping square tubing sheet metal offers many advantages over traditional fabrication methods. For example, CNC laser cutting is much more accurate than other methods of fabrication, allowing for increased efficiency and reduced waste. Additionally, the process is much faster than traditional methods, resulting in shorter production times. Finally, telescoping square tubing sheet metal is much safer than traditional methods, due to the fact that the finished product is much stronger.

Advantages of Telescoping Square Tubing Sheet Metal

The advantages of telescoping square tubing sheet metal are numerous. As mentioned previously, the process is much more accurate than traditional fabrication methods, resulting in increased efficiency and reduced waste. Additionally, the process is much faster, allowing for shorter production times. Finally, the finished product is much stronger than traditional methods, due to the precision-welding techniques used.

Telescoping square tubing sheet metal has a wide range of applications in industries such as automotive, aerospace, and medical. In the automotive industry, telescoping square tubing sheet metal is used to create a variety of components, such as bumpers, frames, and exhaust systems. In the aerospace industry, the process is used to create components for aircraft and spacecraft, such as wings and fuselages. Finally, in the medical industry, telescoping square tubing sheet metal is used to create prosthetics, implants, and other medical devices.

Tips For Telescoping Tube | Metal Supermarkets

In this video blog, we review our top tips for telescoping tube. If you need tube for your next project, visit: metalsupermarkets.com/

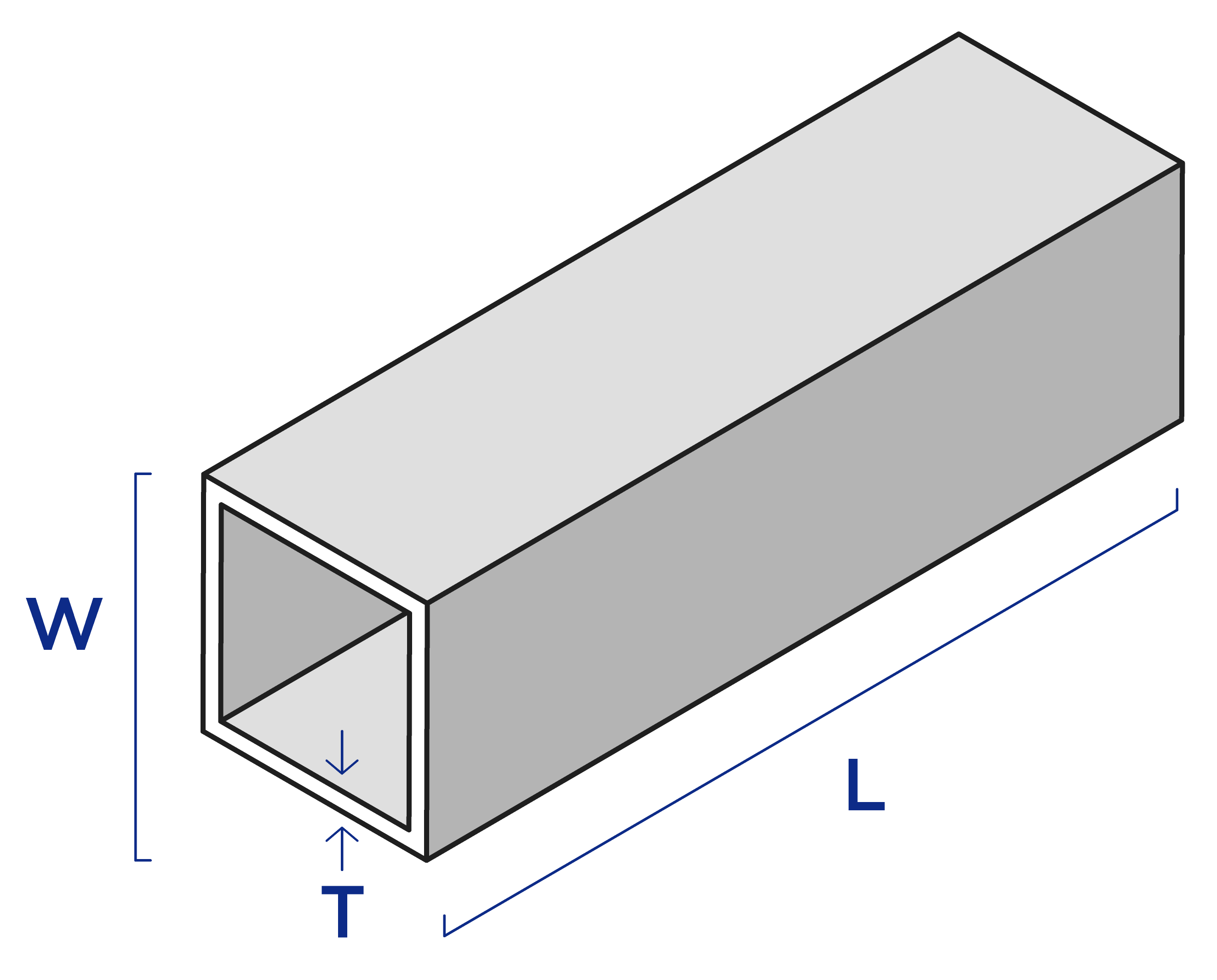

Specs Snapshot: Square-Fit standard perforated tubing comes in seven sizes, from 1.250″ to 2-1/2″ square, in 10 and 12 gauge. Perforated holes are 7/16″ spaced on 1″ centers,. Telescoping Corrosion-Resistant 3003 Aluminum Tubes These tubes are sized so that each tube fits into the next larger size. Ultra-Formable 260 Brass Round Tubes The most., Telescoping Square Tubing Sheet Metal.