6mm Vs 1 4 Tubing

Hey there, fellow tinkerers and curious minds! Ever found yourself staring at two seemingly identical bits of plastic or metal, wondering what the big fuss is all about? Today, we're diving headfirst into a world of tiny tubes. Specifically, we're tackling the epic showdown: 6mm vs. 1/4 inch tubing.

Now, before your eyes glaze over thinking about plumbing or something equally drab, hold up! This isn't your grandpa's pipe fitting tutorial. This is about the nitty-gritty of how things connect, how fluids flow, and why a tiny difference can be a huge deal in the world of DIY, robotics, and even your fancy coffee machine.

Think of it like this: you've got two equally charming puppies. They look alike, they wag their tails, but one might be slightly bigger, just enough to make a difference when they try to squeeze through the same doggy door. That's our tubing in a nutshell!

The Tiny Titans: Let's Get Acquainted

So, what is 6mm tubing? Easy peasy. It's measured in millimeters. Millimeters are super common around the world. Like, everywhere else but here, pretty much. It’s part of the metric system. It’s a nice, round, even number. Six. Millimeters.

And what about 1/4 inch tubing? Well, as the name suggests, it's measured in inches. Specifically, it's one-quarter of an inch. Inches are our good old American friends. They’re what we’re used to, what we grew up with. One-quarter. Inch.

Sounds simple, right? But here's where the fun begins. How big is a millimeter compared to an inch? Are they even close? You might be surprised!

The Conversion Conundrum: When Millimeters Meet Inches

This is where things get delightfully nerdy. We've got a conversion to make! Let's do some quick math, but don't worry, it’s the fun kind of math. The kind that explains why your carefully planned project suddenly looks like a mismatched sock drawer.

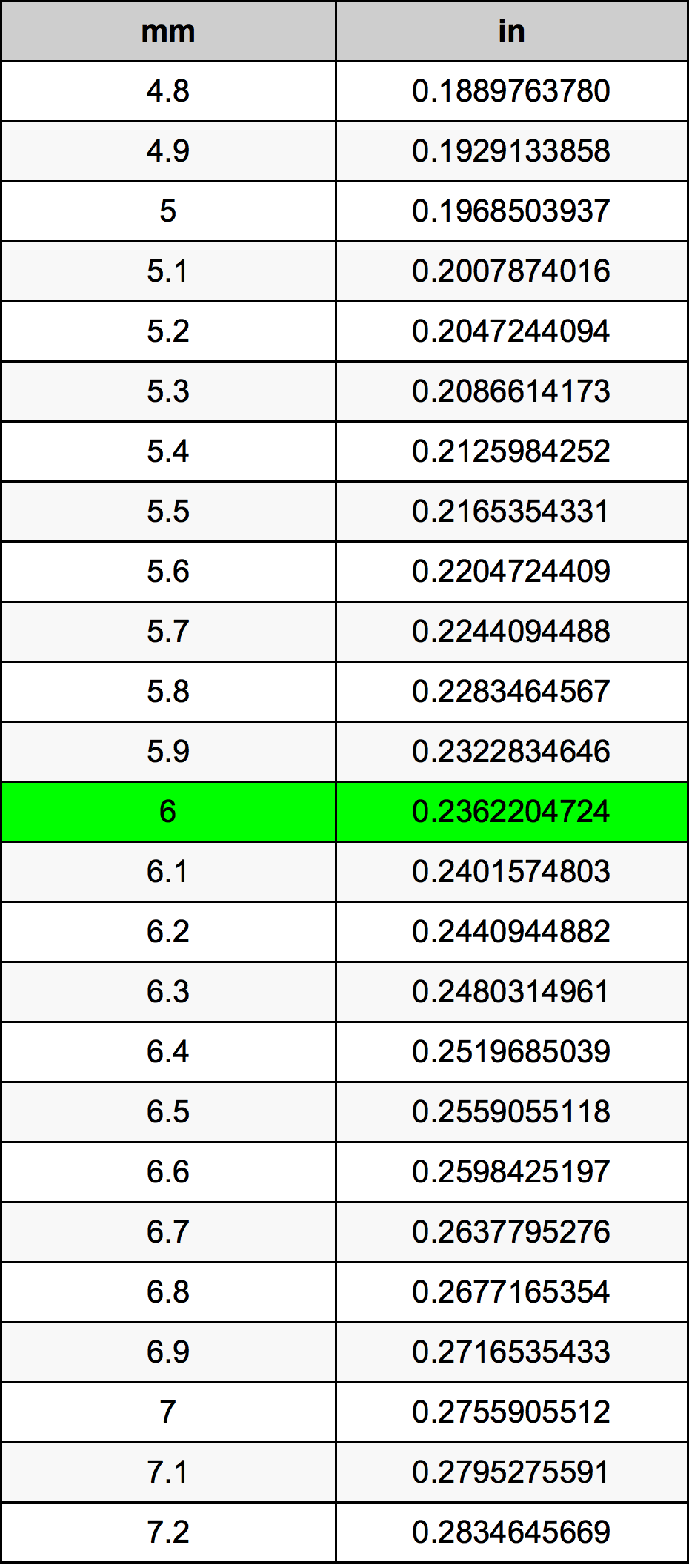

One inch is equal to approximately 25.4 millimeters. Stick with me here.

So, if one inch is 25.4mm, what's a quarter of an inch?

25.4mm / 4 = 6.35mm.

See it? 6mm versus 6.35mm. It’s a difference of just 0.35 millimeters. That’s about the thickness of a few human hairs! It's less than the width of a single grain of sand. It’s tiny.

But in the world of fluid dynamics, or when you’re trying to snap a fitting onto a tube, 0.35mm can feel like the Grand Canyon. It’s enough to make things just not fit, or to create a leak that would make your grandma tut disapprovingly.

Why Should You Even Care About This Tiny Difference?

You might be thinking, "Okay, so it's a tiny difference. So what?" Ah, my friend, the "so what" is where the magic lies! This little discrepancy pops up in so many places:

- DIY Projects Galore: Building a custom water cooling system for your PC? Making a miniature air-powered robot? Trying to set up an irrigation system for your prize-winning petunias? You’ll encounter these tube sizes. And if you grab the wrong one, your project might go from "genius innovation" to "hilarious failure" faster than you can say "oops."

- The World of Pneumatics and Hydraulics: Ever seen those amazing robotic arms that can lift heavy objects with just a puff of air? Or the smooth, controlled movements in industrial machinery? They often use compressed air or hydraulic fluid delivered through tubes. Getting the right size is crucial for proper pressure and flow. A slightly undersized tube could restrict flow, making your robot arm move like it's wading through molasses.

- 3D Printing and Robotics: The maker community loves these sizes! For things like filament drive systems, pneumatic actuators on robots, or even just for routing wires neatly, you’ll see both 6mm and 1/4 inch tubing. Mixing them up is a classic beginner’s mistake. One will probably push in too easily, leading to leaks. The other will be a stubborn mule, refusing to budge.

- Coffee Machines and Water Filters: Yep, even your morning caffeine fix might rely on this precise measurement. Many home appliances use these tube sizes for water lines. Imagine your fancy espresso machine sputtering because the water line is just a hair too loose! Disaster!

The Quirky Details That Make It Fun

Here's the really fun part. This isn't just about boring measurements. It's about a little bit of a global quirk!

The Great Metric vs. Imperial Divide: This is a perfect example of how different measurement systems can cause confusion. For people who grew up with metric, 6mm is intuitive. For those who grew up with imperial, 1/4 inch is second nature. It’s a constant, low-level reminder of our differing measurement habits. It’s like the universal language of "oops, I grabbed the wrong thing!"

The "Will it Fit?" Game: When you're buying fittings, it’s like a mini-game. You have a tube, you have a fitting. Will they play nice? Sometimes, a fitting designed for 1/4 inch will barely accept a 6mm tube, but it'll be loose. Or a fitting for 6mm will be impossible to get onto a 1/4 inch tube. It’s a lesson in precision, learned through trial and error (and sometimes, a bit of frustration).

The Power of a Tight Seal: Why does that tiny difference matter so much? Because many tube fittings rely on a tight friction fit. The tube is squeezed into the fitting, creating a seal that prevents leaks. If the tube is too small, the fitting won't grip it properly. If it's too big, you can't get it in, or it might damage the fitting. It's all about that satisfying snap or the smooth, secure slide.

The "Almost" Problem: This is the most maddening part. They are so close. You might look at them and think, "Yeah, that’ll work." But then you try to push it, and it just won't go. Or it wobbles. Or you force it, and snap, the fitting breaks. It’s the universe reminding you that sometimes, “almost” isn’t good enough.

So, What's the Takeaway?

Next time you’re working on a project that involves tubing, or even just admiring the intricate workings of a gadget, take a moment to appreciate the humble 6mm and 1/4 inch tubes. They’re tiny titans of connection, and their difference, though small, is mighty.

It’s a fun little lesson in precision, a nod to our global measurement habits, and a reminder that even the smallest details can make a big impact. So go forth, tinker wisely, and may your tubes always fit perfectly!