Bearings For Telescoping Tubes. Telescoping square steel tubing is extremely versatile because smaller sizes fit smoothly and snugly into the next larger size. Also known as telescopic steel, this metal tubing. Types include lifting columns, telescoping actuators, bearings, cylinders, jacks, slides and rails. telescopic tubing features include up to 1300 lb. load capacity, 24 VDC.

Telescoping tubes are one of the most common features of industrial machinery and equipment. They are designed to fit inside one another, and when different lengths of them are combined, they can be used to create a variety of different shapes and sizes. One of the most important components of telescoping tubes is the bearings that are used to connect them. These are typically made from a variety of different materials and come in a variety of shapes and sizes, depending on the application.

Also Read

Types of Bearings for Telescoping Tubes

The type of bearing used for telescoping tubes will depend on the application. For example, some bearings are designed to handle large amounts of weight and are often made from steel. Other bearings are designed to provide a smooth and consistent motion, and may be made from a variety of materials such as plastic or rubber. In addition, some bearings are designed to provide a low level of friction, while others are designed to provide a high level of friction.

When selecting a bearing for a telescoping tube, it is important to consider the type of application. For example, if the telescoping tubes will be used in an industrial environment, then a steel bearing may be the best option. However, if the tubes will be used in an agricultural environment, then a plastic or rubber bearing may be more suitable. Additionally, if the tubes will be used in a high-speed application, then a low-friction bearing may be the best option.

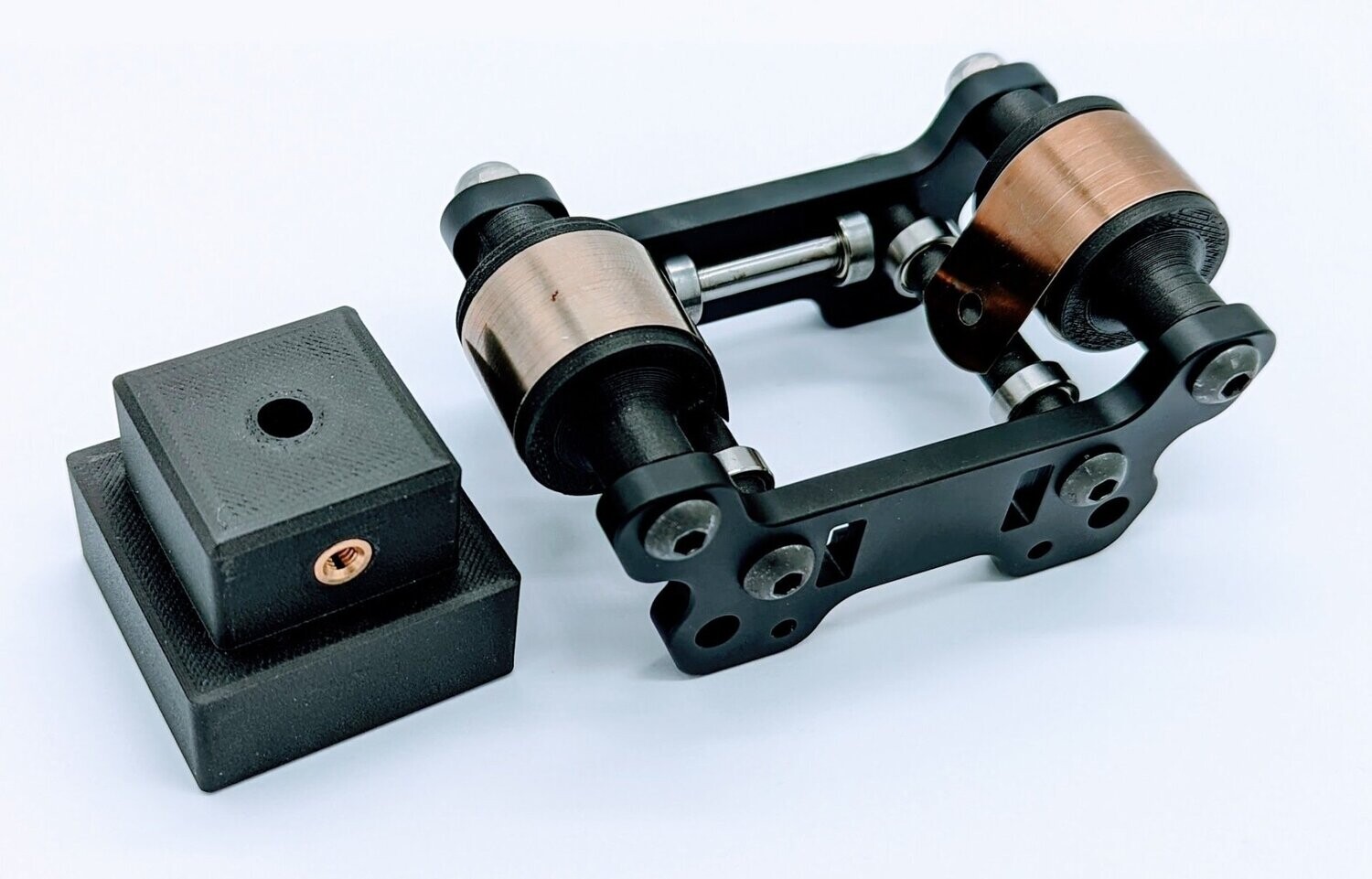

In addition to the material, the shape and size of the bearing are also important factors. Bearings for telescoping tubes come in a variety of shapes and sizes, and the size and shape of the bearing will depend on the application. For example, some bearings are designed to fit into tight spaces, while others are designed to fit into larger spaces. Additionally, some bearings are designed to be more resistant to wear and tear, while others are designed to be more flexible.

Finally, the lubrication of the bearing is also an important factor. Bearings for telescoping tubes are typically lubricated to reduce friction and wear and tear. The type of lubricant used will depend on the application, and it is important to select the right type of lubricant for the application. For example, some lubricants are designed to provide a low level of friction, while others are designed to provide a high level of friction.

Overall, bearings for telescoping tubes are an important component of industrial machinery and equipment. They are typically made from a variety of materials and come in a variety of shapes and sizes, depending on the application. Additionally, the lubrication of the bearing is also an important factor, as it can affect the performance of the bearing. Therefore, it is important to select the right type of bearing and lubricant for the application.

Tips For Telescoping Tube | Metal Supermarkets

In this video blog, we review our top tips for telescoping tube. If you need tube for your next project, visit: metalsupermarkets.com/

Note: Telescoping tube kits are being kitted and will ship out in 1-2 days. Thanks for your patience. Elevate your robot to new heights with the Thrifty Telescoping Tube System. For many people, the term, telescoping bearings brings to mind drawer slides such as those found in our kitchens and offices. But industrial applications. US Factory Manufacturing Telescopic Tubing and Metal OEM Assemblies Since 1919. Custom metal component parts, assemblies, and products. Our specialty is the., Bearings For Telescoping Tubes.