Electrical Nonmetallic Tubing Conduit Coil

Ever stumbled upon a coiled, often brightly colored, flexible tube and wondered what its deal is? It’s not a giant slinky for a superhero, nor is it some futuristic garden hose. This humble yet incredibly important component is known as Electrical Nonmetallic Tubing Conduit Coil, or more commonly, ENT. Think of it as the superhero cape for your electrical wires, protecting them from harm and keeping everything tidy and safe. While it might not sound like the most thrilling topic at first glance, understanding ENT unlocks a world of accessible electrical solutions that make home projects and professional installations a breeze. It’s the unsung hero that allows us to power our lives with peace of mind, and its widespread use in modern construction speaks volumes about its effectiveness and versatility. So, let's dive into why this coiled wonder is such a big deal in the world of electricity!

The Secret Life of ENT: What It Is and Why It Matters

So, what exactly is this ENT Conduit Coil? Imagine a flexible, lightweight, and surprisingly tough tube made from plastic. It's designed to house and protect electrical wires as they snake their way through walls, ceilings, and floors. Unlike its rigid metal cousins, ENT is a dream to work with. Its flexibility means it can bend around corners and navigate tight spaces without needing a whole arsenal of special fittings and tools. This makes it a favorite for electricians and DIY enthusiasts alike. It's often found in specific colors, with orange being a very common hue for residential applications, though you might see gray or white as well, depending on the manufacturer and intended use. This coloring isn't just for show; it can help identify circuits or wire types, adding another layer of practicality.

Unpacking the Perks: Benefits Galore!

Why choose ENT Conduit over other options? The benefits are numerous and quite compelling. First off, there's the ease of installation. Because it's so flexible, you can easily pull it through existing structures or snake it around obstacles. This significantly reduces labor time and the need for complex cutting and fitting, which translates to cost savings. Think about it: fewer bends mean less material and less wrestling with stiff pipes. Furthermore, ENT is lightweight, making it easier to transport and handle on job sites, especially for those working at heights or in confined spaces. Safety is also a major advantage. The plastic construction means it’s non-conductive, providing an extra layer of protection against electrical shock. It's also resistant to corrosion, unlike some metal conduits that can rust over time, especially in damp environments. This durability ensures a longer lifespan for your electrical system.

Another fantastic benefit is its durability against impact. While it’s flexible, it’s not flimsy. ENT is designed to withstand the rigors of construction and the everyday wear and tear of a building. It offers excellent protection against physical damage to the wires inside, preventing nicks, cuts, or crushing that could lead to electrical faults. For those concerned about environmental factors, many types of ENT are also flame-retardant, adding an important safety feature to prevent the spread of fire in the event of an electrical issue. This makes it a smart choice for a wide range of applications, from residential wiring to commercial buildings and even some industrial settings where flexibility and ease of use are paramount.

Where Does This Coiled Champion Show Up?

You’ll find ENT Conduit Coil in a variety of places. It’s a staple in residential construction, particularly for wiring in walls, attics, and basements. It’s also frequently used in commercial buildings for areas where flexibility is needed, like in office spaces or retail environments. Think about running power to a display shelf or a workstation; ENT makes it easy to adapt as the layout changes. It’s also a popular choice for exposed ceiling applications in certain types of buildings, where its flexibility allows for creative routing around beams and other structural elements. In some specific applications, it can even be used for underground installations, though this often requires specialized types of ENT or additional protective measures. Basically, anywhere you need to run electrical wires safely and efficiently, and where the ability to bend and flex is a bonus, you’re likely to encounter this coiled marvel.

One of the most common and practical uses for ENT is within exposed concrete slabs or precast concrete. During the pouring of concrete, electricians can embed the flexible ENT, creating pathways for future wiring. Once the concrete cures, the ENT remains in place, ready to have wires pulled through it. This method is incredibly efficient and ensures that wiring is protected within the very structure of the building. It's also frequently seen in hollow block walls, where it can be easily threaded through the cavities. For renovations or additions, where it might be difficult to run rigid conduit, the flexibility of ENT makes it a much simpler and less disruptive solution. Its ability to navigate around existing plumbing, HVAC systems, and structural supports makes it an invaluable tool for modern construction and remodeling projects. The coils themselves are also designed for easy handling and dispensing, often coming in lengths that are manageable for a single person to work with.

Making it Happen: Installation Tips and Tricks

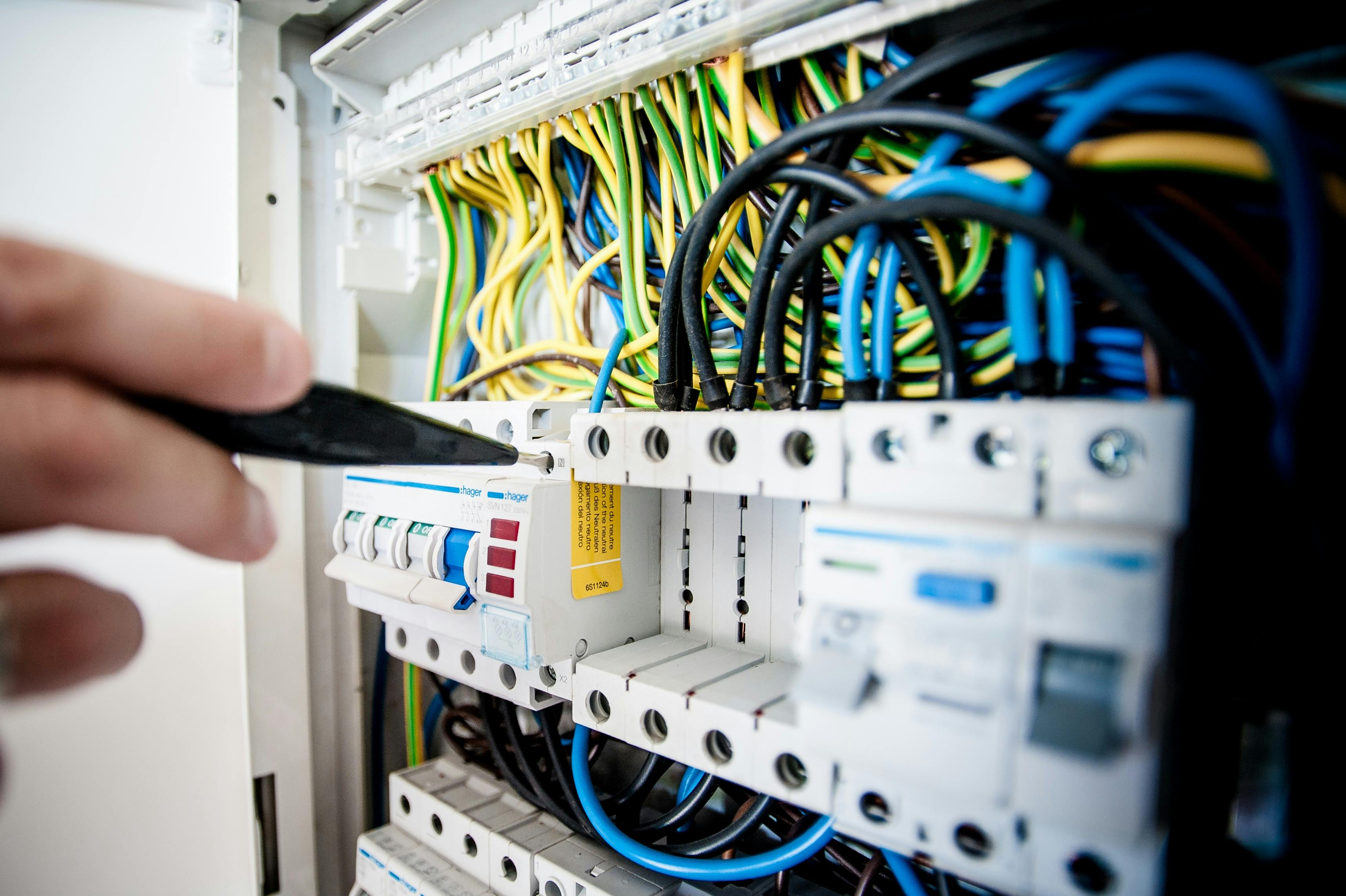

Working with ENT is generally straightforward. It’s typically cut with a simple utility knife or a specialized plastic pipe cutter. To connect sections of ENT or to attach it to electrical boxes, special connectors and fittings are used. These are usually snap-fit or secured with a solvent cement, depending on the type of fitting. The real magic happens when you need to pull wires. While you can do this by hand for shorter runs, for longer distances, electricians use fish tape – a long, flexible metal or fiberglass tape – to pull the wires through the conduit. The smooth interior of the ENT makes this process much easier compared to rougher conduit types. Remember to always follow local electrical codes and consult with a qualified electrician if you’re unsure about any aspect of your project. Safety first, always!

When you're looking to purchase Electrical Nonmetallic Tubing Conduit Coil, you'll find it available in various diameters to accommodate different numbers and gauges of wires. The common sizes range from 1/2 inch up to 2 inches or even larger for industrial applications. The "coil" aspect refers to how it's packaged and sold; it comes neatly coiled into manageable lengths, making it easy to transport, store, and unroll on the job. This coiled form factor is a key part of its user-friendliness. For those planning a project, it’s wise to estimate the total length of conduit needed and then add a bit extra for any mistakes or unexpected turns. Checking the specific requirements of your local building codes for acceptable conduit types and installation methods is also a crucial step before starting any electrical work. The sheer popularity and widespread adoption of ENT are a testament to its blend of flexibility, durability, and cost-effectiveness.