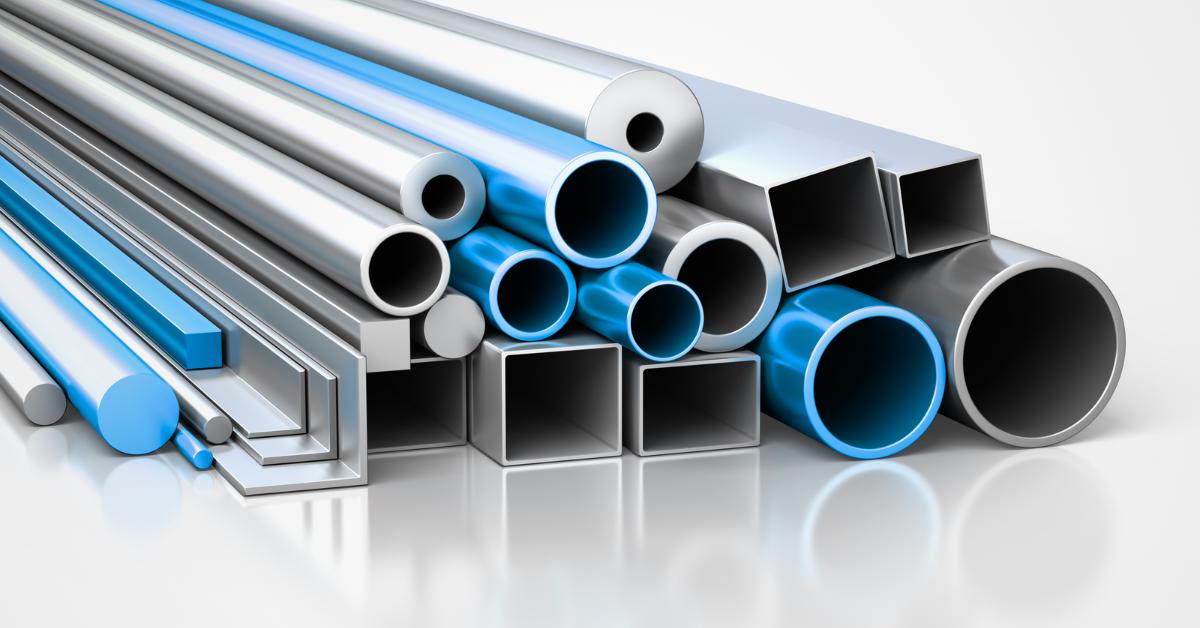

Telescopic tube has many styles and shapes each for specific applications. Make sure you know this variant to give you the perfect telescopic tube for your project.

Types of Telescopic Tubes

The two main types of telescopic tubes are round and square. Round tubes are open-ended and are used for creating tubes with a diameter that is larger than the outside tube. Square telescopic tubes are closed at each end and can be used to create components with larger widths. In addition, telescopic tubes can be made from a variety of materials, including aluminum, steel, and plastic.

Also Read

Round Telescopic Tube

Round telescopic tubes are round, cylindrical shapes that are hollow. This steel tubing shape offers the strength and durability you need at an affordable price. Round steel stubbing can be used for almost any application.

Round telescopic tubes have a wide variety of structural and architectural applications. Unlike pipes, tubes are measured by their outside diameter and their wall thickness. Some examples of tube applications would be automotive parts, railings and patio furniture.

Round telescopic tube shapes can be purchased online and/or from your local markets. It can be cut to your exact specifications.

Rectangular Telescopic Tubing

This telescopic tube shapes is designed for structural applications and manufacturing industries. It offers more strength and rigidity than other shapes, making it ideal for construction, architecture, automobiles, and more.

Rectangular tubes are formed from coils and then ran through a series of dies. They are are welded from the inside to form their shape.

Rectangular Tube is commonly available in Aluminum, Stainless Steel, Hot Rolled Steel and Cold Rolled Steel. It can be cut to your exact specifications.

Square Telescopic Tube

Square tubes are formed from coils and then ran through a series of dies. They are welded from the inside to form their shape. Square tubes are generally used for maintenance and structural purposes. Some examples of applications would be building construction, railings, and sign posts. They are measured by their outside dimensions and their wall thickness.

This square telescopic tube shapes can withstand extreme temperatures, pressures, and the elements, making it perfect for both commercial and industrial applications. It is used frequently in truck beds, trailer components, and machine parts.

Shapes of Telescopic Tubes

Telescopic tubes can be made in a variety of shapes, including round, square, rectangular, and hexagonal. Round tubes are open-ended and are used for creating tubes with a diameter that is larger than the outside tube. Square tubes are closed at each end and can be used to create components with larger widths. Rectangular tubes are closed at each end and can be used to create components with larger widths and depths. Hexagonal tubes are closed at each end and can be used to create components with larger widths and heights.

In addition to the basic shapes, telescopic tubes can also be made in a variety of more complex shapes, such as oval, triangular, and octagonal. These shapes are used for creating components with more intricate shapes and designs. They are also used for creating components with more intricate details and curves.

Steel Materials

Hot Rolled Steel Tubing

This steel tube has been processed using very high temperatures and a series of rollers to make it easier to work with. Hot rolling keeps the material free from internal stresses. This type of tubing is found frequently in the construction industry, but not for precise applications.

Cold Rolled Steel Tubing

This steel tubing begins as hot rolled steel but is processed even further to create a more finished surface and provide additional strength. This process is more suited for applications that have strict tolerance, straightness, and surface condition requirements because cold rolling is a more precise finishing method.

Aluminum Steel Tube

Aluminum is a silver-colored, low density metal. It finds use in a huge variety of commercial applications. The Unalloyed type is ductile, exhibits moderate strength, and is very resistant to corrosion under most circumstances. Aluminum can be dramatically strengthened by the addition of appropriate alloying elements (Cu, Mg, Mn, Si, etc.) and subsequent heat/work treatments. It is commonly used in both wrought and cast forms.

The low density of this aluminum telescopic tube results in its extensive use in the aerospace industry, and in other transportation fields. Its resistance to corrosion leads to its use in food and chemical handling (cookware, pressure vessels, etc.) and to architectural uses.

Stainless Steel Tube

Stainless steel is a steel alloy with increased corrosion resistance compared to carbon/alloy steel. Common alloying ingredients include chromium (usually at least 11%), nickel, or molybdenum. Alloy content often is on the order of 15-30%. Common applications include food handling/processing, medical instruments, hardware, appliances, and structural/architectural uses.

Stainless steel telescopic tube shapes is available in a wide variety such as bar stock, channel, beam, angle and more.

Galvanized Steel Tube

This steel tube has been treated with a galvanized coating that makes the material more resistant to corrosion and extends the material’s life. Because the material is corrosion-resistant, it is often used for structural tubing in projects like bridges and fences where it may be subjected to environmental conditions.

Hammered Steel Tube

This tubing offers a decorative tubing design that also provides added strength and welding capabilities. It is used for a variety of decorative applications.

Telescopic tubes are an essential component in many industries. They can be used to create a variety of structures and components, depending on the application. Telescopic tubes are available in a variety of shapes and sizes, and can be made from a variety of materials, including aluminum, steel, and plastic. Depending on the application, telescopic tubes can be used to create a variety of structures and components.