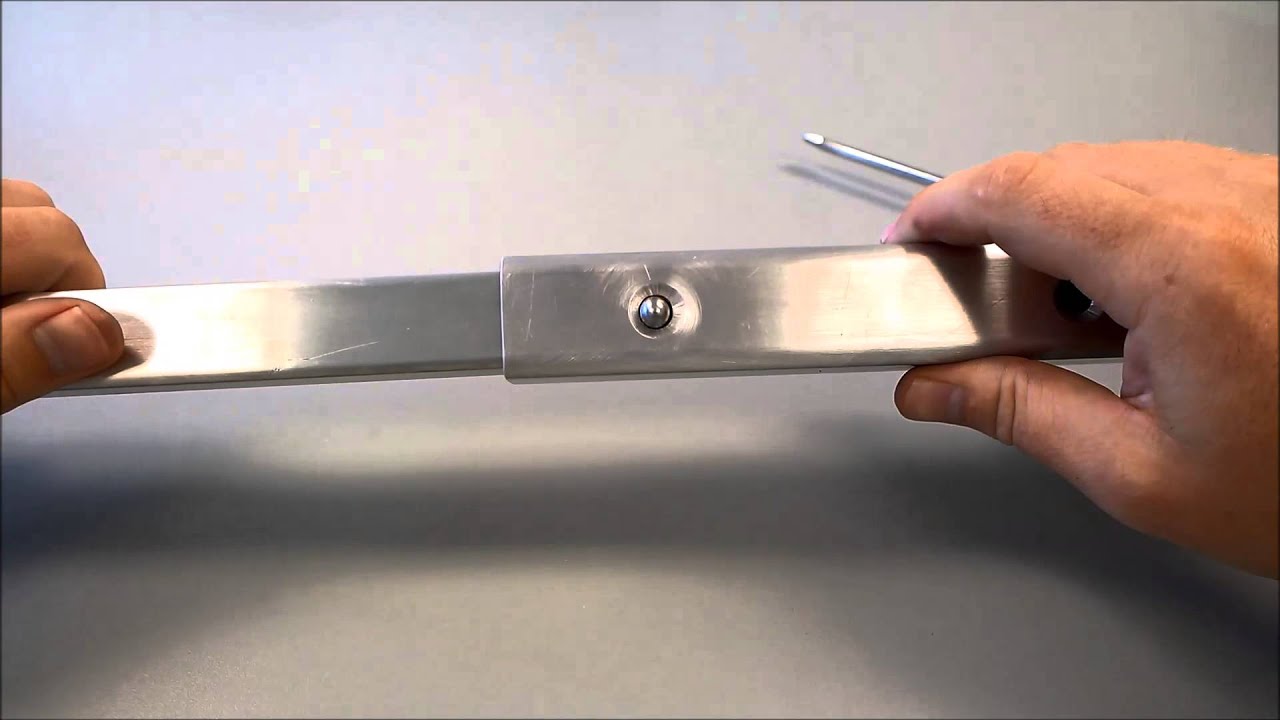

Tube Telescoping Pin Connection. Square HSS Connections with Rotated Branches. Rotation of just the branch (or branches) of a connection by 45 ° about the member axis produces a connection with a larger. Telescoping pins — also referred to as pin-in-pin and telescopic pins — function by nesting one smaller pin within a larger, outer pin such that each pin can move. These pins use spring force to hold pieces of telescoping tubing together. Install them in the smaller tube, then slip the larger tube over the smaller tube until the button pops into a.

Tube telescoping pin connections are an essential part of many metallurgical engineering projects. These connections are used to join two or more tubes together in order to create a secure, reliable connection. In this article, we will discuss what tube telescoping pin connections are, how they work, and their advantages and disadvantages.

Also Read

What Is a Tube Telescoping Pin Connection?

A tube telescoping pin connection is a type of connection used to join two or more tubes together. The connection consists of two parts: a male pin and a female pin. The male pin is inserted into the female pin, and then the two pins are locked together with a set screw. This type of connection is used to join tubes together securely and reliably.

The pins used in a tube telescoping pin connection are typically made from steel or stainless steel. The pins are often tapered, so that they can be inserted into the female pin without too much effort. The pins are also designed to be durable and resistant to corrosion.

How Does a Tube Telescoping Pin Connection Work?

The tube telescoping pin connection works by inserting the male pin into the female pin. The pins are then locked together using a set screw, which is usually located on the side of the female pin. The set screw is tightened with a wrench, and the two pins are then securely joined together.

The pins are designed to be very strong, so they can withstand a lot of force and pressure. This means that the connection will remain secure even when subjected to heavy loads or extreme temperatures. The pins are also resistant to corrosion, so they will last for many years.

Once the connection is made, it can be easily disassembled. All that is required is to loosen the set screw and remove the male pin from the female pin. This makes the connection quick and easy to install and remove.

Advantages of Tube Telescoping Pin Connections

There are many advantages to using tube telescoping pin connections. First, they are easy to install and remove. This makes them ideal for projects that require frequent assembly and disassembly. Second, they are strong and reliable. The pins are designed to withstand heavy loads and extreme temperatures, so they are very durable. Finally, they are corrosion-resistant, so they will last for many years.

Disadvantage of Tube Telescoping Pin Connections

The main disadvantage of tube telescoping pin connections is that they are not very flexible. The pins are designed to be very strong, so they cannot be easily bent or twisted. This means that the connection must be made in a straight line. If the connection needs to be made in a curved or angled shape, a different type of connection must be used.

Conclusion

Tube telescoping pin connections are an essential part of many metallurgical engineering projects. They are easy to install and remove, strong and reliable, and corrosion-resistant. The main disadvantage is that they are not very flexible, so the connection must be made in a straight line. However, for most applications, tube telescoping pin connections are an ideal choice.

Installing Locking Button in Telescoping Tube

Here is a quick video on how to install the locking buttons in telescoping tube. This is the 1" tube that fits inside 1 1/4"

Tubes can be made telescoping when one fits over the other with only small clearance. if you can squeeze the larger tube, you can make a very, very strong linkage which is. Telescoping is required when the ability to adjust tubing or piping to account for an unknown or constantly-changing width is essential. Examples. Locking & telescoping mechanisms for composite tubes Flip lock clamps & twist lock rings Button clips & ball lock pins We pride ourselves in the amount of accessories we offer,., Tube Telescoping Pin Connection.